From production and packaging to surgical environments, robots are performing increasingly complex tasks, faster and with more precision than ever before. In operating theatres, for example, robots can perform complex surgeries with such repeatable accuracy that associated risk to the patient has dramatically fallen, while recovery time has increased.

Our relationship with industrial robots is also changing. On the factory floor, collaborative robots are breaking out of the cages that have traditionally confined them, to work in the open alongside people.

These developments have been made possible by advancements in motor, actuator and sensor technology as well as the all-important bearing. Hybrid chrome and steel bearings, ceramic bearings and slewing bearings are all common in robotic applications, but thin section bearings also have a key role to play, but these can be overlooked by engineers.

Low space requirement

Thin section bearings deliver higher speeds, improve efficiency, offer higher levels of design flexibility as well as reduce friction. And, because there is very little difference in size between the internal and external ring, they also reduce the weight and bulk of an application, making them an ideal choice for robotics, where both footprint and weight are premium items.

However, because they are so thin, particular attention should be paid to the roundness of the ring itself. If you take a thin section bearing without any lubricant and spin the inner ring, a light squeeze of the outer ring will stop the bearing in its tracks, thanks to the flex in the device.

As a result, the manufacturing process must be extremely precise to ensure the highest possible degree of roundness in both rings, as well as good noise levels in the bearing itself. This will normally call for fine grinding and machining, complimented by a very high level of quality in both the process and the raw materials. If the rings are not perfectly formed, even a minute discrepancy will stop the bearing running smoothly, producing excess noise.

As a result, the manufacturing process must be extremely precise to ensure the highest possible degree of roundness in both rings, as well as good noise levels in the bearing itself. This will normally call for fine grinding and machining, complimented by a very high level of quality in both the process and the raw materials. If the rings are not perfectly formed, even a minute discrepancy will stop the bearing running smoothly, producing excess noise.

These thin-section ball bearings can be supplied open, shielded or sealed in SAE52100 chrome steel or 440 grade stainless steel and are designed to withstand some radial loads as well as moderate thrust loads in both directions. Some of the smaller thin-section bearing sizes are also available with a fibreglass reinforced nylon high speed synthetic retainer.

Thin section lubrication

You should choose a low torque, free turning and low noise grease for a thin-section bearing, as an overly stiff grease won’t deliver the best results and could increase bearing torque to unacceptable levels.

A grease with a temperature range of -40 to 150°C would be most suitable as this reflects the variety of applications in which a robot is most likely to be used, from refrigeration to locations near a furnace. It’s also important to select a food grade grease if the robot is going to be used in food or beverage production or packaging.

The right grease choice will result in a free running bearing, which in turn will reduce the power consumption of the machine itself, as well as the long-term maintenance costs. It is also one of the factors that can contribute to the overall speed of the robot arm.

So, while humanoid robots may not be cleaning our homes, it does seem likely that their impact on industry will continue to increase apace.

About the author:

Chris Johnson is managing director of precision bearings provider SMB Bearings

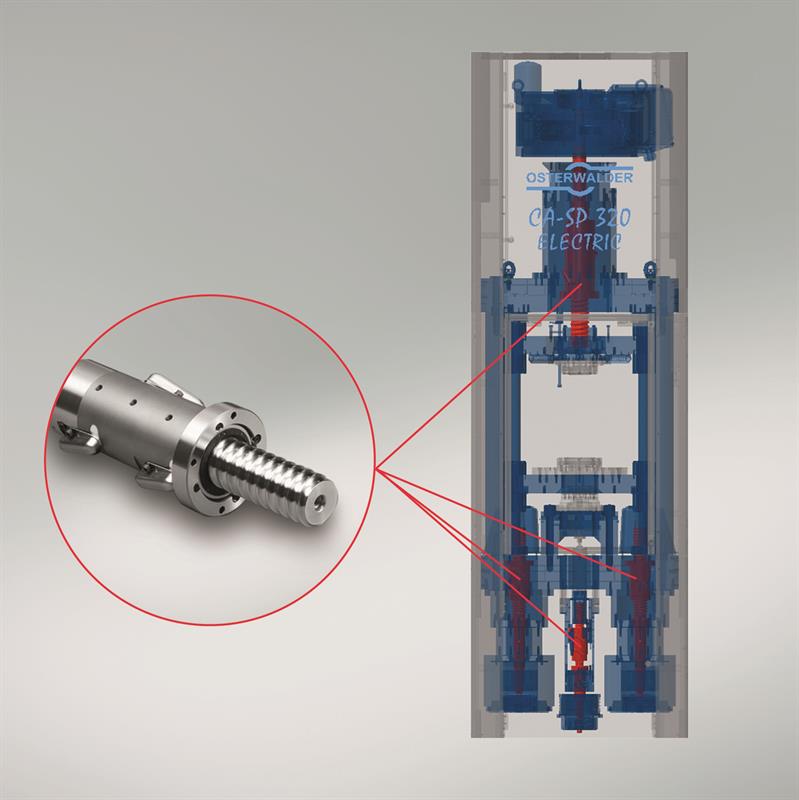

Ball screws replace hydraulics in powder presses Switzerland-based Osterwalder has replaced hydraulic drives with servo-electric drives featuring NSKs HTF (High Trust Force) series ball screws. The new systems are said to achieve an 80% reduction in energy consumption and produce pressed parts with higher dimensional accuracy. Precise synchronisation of movement is important as any interruptions or irregularities in the process can lead to dimensional errors, or cracked inserts during sintering. This also reduces the amount of finishing work required and cuts process and material costs. Michael Sollberger, development engineer at Osterwalder, confirms: “We can position these systems to within 1μm and achieve very high repeatability levels.” The presses now take up less space and servicing is reduced as there are no hydraulic control valves or other high-maintenance components, while working temperatures are more constant as no heat is being produced by the hydraulic system. Noise reduction is another benefit, as Sollberger explains: “Our hydraulic systems operate at just below the 75dB limit, whereas the servo-electric systems are very quiet, only 58 to 60dB.” As well as carbide pressed parts, the technology is equally applicable to components made from iron powder, ceramic and magnetic materials. |