The demonstrator, called the ‘E-Fan X’, will be fitted on a BAe 146 flying testbed and is anticipated to be flown as soon as 2020 following a comprehensive ground test campaign. As part of the tests, one of the aircraft’s four gas turbine engines will be replaced by a 2MW electric motor. Later, once the E-Fan X has been proven, a second gas turbine will be replaced.

Paul Eremenko, Airbus’ chief technology officer, says: “We see hybrid-electric propulsion as a compelling technology for the future of aviation.

“The E-Fan X is an important next step in our goal of making electric flight a reality in the foreseeable future. The lessons we learned from a long history of electric flight demonstrators – starting with the Cri-Cri, including the e-Genius, E-Star, and culminating most recently with the E-Fan 1.2, as well as the fruits of the E-Aircraft Systems House collaboration with Siemens – will pave the way to a hybrid single-aisle commercial aircraft that is safe, efficient, and cost-effective.”

Airbus, Rolls-Royce and Siemens will each contribute know-how in their respective fields of expertise as part of the E-Fan X programme.

Airbus, Rolls-Royce and Siemens will each contribute know-how in their respective fields of expertise as part of the E-Fan X programme.

The E-Fan X demonstrator will explore the challenges of high-power propulsion systems, such as thermal effects, electric thrust management, altitude and dynamic effects on electric systems and electromagnetic compatibility issues.

The objective is to push and mature the technology, performance, safety and reliability to enable quick progression of the hybrid-electric technology.

The programme also aims to establish the requirements for future certification of electrically powered aircraft while training a new generation of designers and engineers to bring hybrid-electric commercial aircraft one step closer to reality.

As part of the E-Fan X programme, Airbus, Rolls-Royce, and Siemens will each contribute experience and know-how in their respective fields of expertise:

- Airbus will be responsible for overall integration as well as the control architecture of the hybrid-electric propulsion system and batteries, and its integration with flight controls.

- Rolls-Royce will be responsible for the turbo-shaft engine, 2MW generator, and power electronics. Along with Airbus, Rolls-Royce will also work on the fan adaptation to the existing nacelle and the Siemens electric motor.

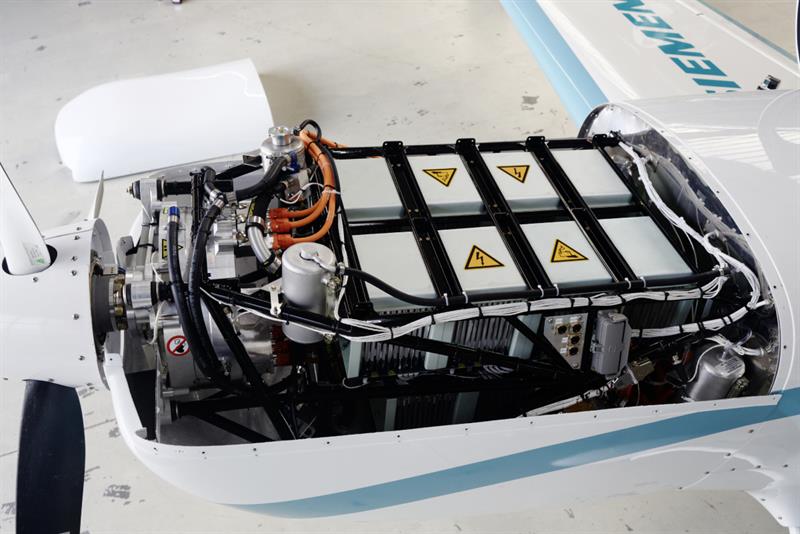

- Siemens will deliver the 2MW electric motors and their power electronic control unit, as well as the inverter, DC/DC converter, and power distribution system. This comes on top of the E-Aircraft Systems House collaboration between Airbus and Siemens, launched in 2016, which aims to develop and mature various electric propulsion system

- components and their terrestrial demonstration across various power classes.

Dr Frank Anton, head of Siemens eAircraft; Mark Cousin, Airbus head of demonstrators; Paul Stein, Rolls-Royce CTO

Paul Stein, chief technology officer at Rolls-Royce, says: “The E-Fan X enables us to build on our wealth of electrical expertise to revolutionise flight and welcome in the third generation of aviation. This is an exciting time for us as this technological advancement will result in Rolls-Royce creating the world’s most powerful flying generator.”

One of the biggest challenges for the aviation sector is the move towards a means of transport with improved environmental performance, which is more efficient and less reliant on fossil fuels. The E-Fan X project partners have committed to meeting the technical environmental goals set out by the European Commission’s Flightpath 2050 Vision for Aviation that stipulates a 60% reduction in CO2, reduction of NOx by 90% and noise reduction by 75%.

These cannot be achieved with existing technologies. Therefore, Airbus, Rolls-Royce and Siemens are focusing research work in different technology areas including electrification. Electric and hybrid-electric propulsion are seen as among the most promising technologies for addressing these challenges.

“Siemens has been driving innovation in core technology fields at full speed,” says Roland Busch, chief technology officer of Siemens. “In April 2016, we opened a new chapter in electric-mobility with the collaboration with Airbus. Building up electric propulsion for aircraft, we are creating new perspectives for our company and also for our customers and society. With the E-Fan X partnership, we now take the next step to demonstrate the technology in the air.”

Siemens electric motor sets air-speed records In March 2017, the Extra 330LE aerobatic plane, powered by an electric propulsion system from Siemens, set two new speed records. At the Dinslaken Schwarze Heide airfield in Germany, the electric aircraft reached a top speed of 337.50kph over a distance of 3km, 13.48kph faster than the previous record set in 2013. The World Air Sports Federation (FAI) officially recognised the record flight in the category ‘Electric airplanes with a take-off weight less than 1000kg’. In a slightly modified configuration with an overall weight exceeding 1 tonne, The Extra also set a new FAI world record in the category ‘above 1000kg’ reaching 342.86kph. The Extra 330LE also became the world’s first electric aircraft to tow a glider in to the sky. The plane took a type LS8-neo glider up to a height of 600m in only 76s. “This aerotow provides further highly visible evidence of our record-setting motor’s performance capabilities,” says Frank Anton, head of eAircraft at the Siemens venture capital unit next47. “Just six such propulsion units would be sufficient to power a typical 19-seat hybrid-electric airplane.” In addition, the lightweight electric motor already held a world record for power-to-weight ratio: weighing just 50kg, it supplies a constant electric output of 260kW, which is five times more than comparable propulsion systems.

Currently, there are no plans for series production of this electric plane. However, electric propulsion systems are scalable and Siemens, Airbus and Rolls-Royce intend to develop hybrid-electric regional aircraft based on this record-setting motor. “By 2030, we expect to see the first planes carrying up to 100 passengers to have a range of about 1000km,” claims Anton. |

As an aerobatic plane, The Extra 330LE serves as the flying test bed for the new propulsion system and is particularly well suited for taking the components to their stress limits, for testing and enhancing them.

As an aerobatic plane, The Extra 330LE serves as the flying test bed for the new propulsion system and is particularly well suited for taking the components to their stress limits, for testing and enhancing them.