A standard, off-the-shelf pressure sensor refers to one where the specification or build standard remains unchanged. The term ‘custom’ or ‘customised’ refers to a pressure sensor that is based on a standard product but either the software or hardware has been modified so that it meets a specific requirement.

For example, a customised pressure sensor might be a standard unit but fitted with a special subsea connector, high temperature electronics, a modified housing, or a specific communications interface.

The most obvious reason to choose a custom pressure sensor is that there is not a standard ‘off-the-shelf’ sensor that meets all of the requirements. In addition, contrary to popular belief, custom sensors are not necessarily just for unusual one-offs or small batches. They are often the most appropriate choice for higher volume, mainstream applications up to 10,000 pieces.

Quite simply, not every pressure sensing challenge can be solved with a standard sensor solution. If a pressure sensing application, for example, requires some kind of modification it can often be more cost effective to outsource this to a third-party sensor supplier with the necessary skills, experience and in-house engineering design services.

Working from original or customer-supplied drawings, a reputable supplier can often incorporate advanced engineering techniques and field-proven mechanical design best practices to create a robust, cost-optimised solution that is fully in-house tested.

Other reasons for choosing a custom sensor is the end use environment, which can often pose high risks of contamination, corrosion, high temperatures, high vibration, overpressures or combustion. In more extreme cases, they can also involve highly flammable liquids or gases.

In these cases, a carefully designed custom (or fully bespoke) engineered pressure sensor may be the most suitable option. Even if you think you or your end user customer’s application is unique, if you contact a reputable sensor supplier, there’s every chance their engineers have seen a similar application before.

Even if you’re lucky enough to find a standard sensor that fits a demanding specification, it is likely that such a sensor will have a mechanical form, electrical interface and functionality that has been designed for a group of applications rather than your specific one. This means you’ll be paying for hardware and functionality that you may not require. You may also need to modify the design of your host equipment to accommodate a standard unit. This means your overall unit costs may actually increase by purchasing standard off-the-shelf sensors rather than custom versions.

Applications

In one example, a transmitter with a subsea series electrical connection was designed to operate in applications where the external pressure applied on the housing and electrical connection could reach as high as 400bar. Utilising a subsea series electrical connection and by hydrostatically testing the product to ensure it met these requirements, a suitable custom pressure sensor was developed.

In another example, a stainless steel pressure sensor was designed to measure 12bar of concrete slurry being pumped along a delivery line. In this application, there is a possibility that blockages can occur and pressures can reach as high as 200bar. Therefore, the pressure sensor was custom designed to withstand this level of pressure without rupturing.

Designed with an ANSI 1500 flange and secondary containment, the sensor design ensures a rugged failsafe solution. They are rated to IP67 to withstand the concrete piling conditions on site. The sensor is a unique, flush-mounted design with a special polyurethane protective cover on the diaphragm, which acts as an effective mechanical filter to ensure that the aggregates in the concrete do not destroy the sensor element.

Impress is an ISO 9001 accredited company, with more than 25 years’ experience in instrumentation design and manufacturing for a diverse range of applications. In addition to its standard range of pressure, level, distance and temperature instrumentation products, Impress offers a customised design service for customers that require non-standard instruments. These services are provided by a dedicated team of highly qualified professional engineers with experience of electronics, software, mechanical engineering and instrument design. 65% of all instrumentation products sold by Impress Sensors are custom designed.

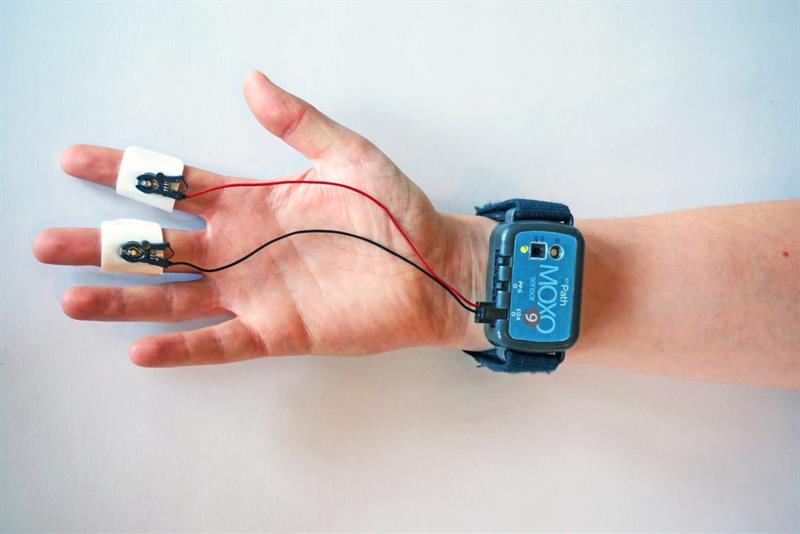

Wearable device reveals consumer emotions

Humans experience a range of emotions in response to products and experiences on a daily basis. Shoppers may get excited for certain brands and then overwhelmed by choices. Audience members may oscillate between apathy and engagement during performances. Using wearable stress sensors, analytics, and other technologies, MIT Media Lab spinout mPath is able to pinpoint the exact moment consumers feel these subconscious responses. In doing so, the startup has brought some interesting market research insights to major companies to help them refine their products and services. “Companies struggle to understand their customers’ emotional needs or wants,” says founder and CEO Elliot Hedman. “But if we listen to consumer emotions, there’s a lot of room for innovation.” ‘Emototyping’ The startup’s MOXO sensor — the core technology of which was co-invented by Hedman — is a wearable that resembles a bulky smartwatch. Placed on the wrist, it wirelessly measures changes in skin conductance (subtle electrical changes across the skin), which reflect sympathetic nervous system activity and physiological arousal. Spikes in conductance can signal stress and frustration, while dips may indicate disinterest or boredom. To gain an accurate picture of consumers’ responses to specific stimuli, mPath has developed a new approach to market research, called ‘emototyping’. The process combines the stress sensors with eye-tracking glasses or GoPro cameras to identify where a person looked at the exact moment of an emotional spike or dip. Personal interviews are also conducted with all participants who are shown the data and asked what they think they felt. This entire process reportedly creates a more in-depth precise emotional profile of consumers than traditional market research, which primarily involves interviews and occasionally video analysis. A study with the New World Symphony found that making songs shorter and performing classical compositions of modern pop music help engage new audiences in classical music. |