Migration of manufacturing is not always an easy thing to analyse. For very high volume, low value products it was obviously just a question of economies of scale and cheap labour, but it is less clear in other markets. Last year, for example, the UK made 1.5 million cars, a seven year high, and it was one of those stalwart British industries that only a few decades ago seemed to be in terminal decline. So why should the same not be true in other markets? Will we again see the rise of the computer and mobile phone markets? What about domestic appliances? And in particular washing machines?

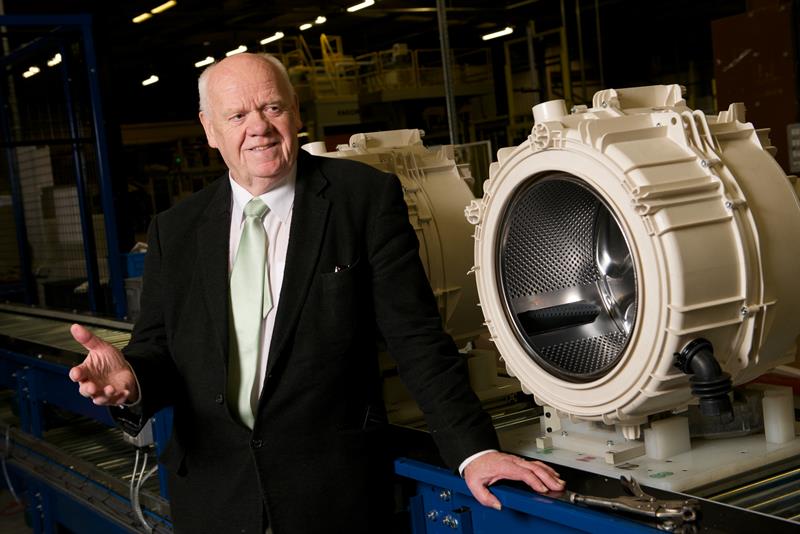

Pamela Petty is Managing Director of Ebac, a company poised to reintroduce washing machines that will be both designed and built in the UK. The decision to go down this path was not without some soul searching. “It did make me think that I’d missing something fundamental - why had everybody moved out of the UK?” admitted Petty. “We’re talking about great companies, and if they couldn’t afford to manufacture here with their buying power and big scale operations, then how could we?”

But further investigation did not clarify the situation, there was not one single reason. Some companies merged and then ‘globalised’, but there was little evidence of washing machine plants shutting down because they were not profitable.

What is more is that Ebac, founded by Petty’s father John Elliot, had forty years experience making dehumidifiers and more recently water coolers – the latter being introduced as to provide seasonal balance to production of the former. “It was the perfect summer product to compliment our winter product,” said Petty. “We developed and patented a water trail system that provided a completely hygienic solution to sanitisation of the coolers and dealt with concerns about open reservoirs and bacteria growth. Our water trail system swapped as easily as a printer cartridge would swap, and that meant that the training was easy for the delivery drivers to do it.”

The company had grown both products to over 100,000 units annually. But during the 90s it was clear that change was needed. Petty said: “Eventually the industrialisation of cheaper labour markets hit us too, and we lost enough market share to hurt us. Though we tried to compete by becoming leaner, inevitably we had to re-think our survival.”

"We buy three million washing machines every year in the UK and every single one of them was imported. I couldn’t get over that." - Pamela Petty |

Various flirtations with white goods, particularly involving a Turkish freezer manufacturer, appeared to have hit the buffers when Petty attended a seminar in 2012 on Regional Growth Funds (RGF) – Government funding for private sector projects that will protect or create jobs. Plans for manufacture of fridge freezers were already on hand but further research showed that washing machines might be a better initial market. Three million are bought in the UK every year but none of them made here. A second attempt at RGF was successful - £1m was awarded towards capital costs and investment – with a plan to develop and launch a range of washing machines within 18 months.

Petty confessed: “I have to say, my plan was a little optimistic in terms of time. It’s taken nearly double that, although we have pretty much hit the budget cost for the base model and the production equipment and tooling. In my defence, we did in the middle of it all move a chest freezer production facility from John O’Groats to Newton Aycliffe. When the business that made the much loved Norfrost brand of chest freezers went into liquidation in 2013, we bought that equipment which would at least give us a start in refrigeration which was part of the RGF application as well.”

Making the switch to washing machines was not straightforward. “We had to learn everything, absolutely everything,” claimed Petty. “The project was not as simple as a different application of existing technologies, things that we were familiar with. So we decided early on in the project to buy in the expertise. We bought the oscillating group and the software development for the wash programmes. We selected European manufacturers for critical components that we couldn’t make ourselves, companies with a track record for these components.”

There are more than 500 different washing machine models available in the UK and so in a bid to offer a complete range that would offer an alternative to the majority of them, a modular approach to the design was settled on. This has given Ebac complete flexibility to put together any combination of drum size, spin speed, motor technology, user control, energy rating and even colour. The first combinations will be aimed at the ’safe zone’ – the highest demand sectors of the market according to surveys of consumers, retailers, staff, friends, family...virtually everyone is a washing machine user and has opinions about what they want form them.

It was important to have something different to offer the market and there are, initially, two niche areas that the company believe are worth exploiting. The first is technology driven – touch screens. These are entering the market but principally on top end models, so Ebac’s range will include affordable touch screen options. The second niche, which Petty concedes is a bit of hunch, is to bring hot fill back to washing machines.

Acceptance for the touch screen idea was verified by an online survey, but Petty believes it is an idea that could be taken a step further. “We can combine it with an app so that we can actually help the visually impaired to do their washing without having to guess where the dial is and just randomly select programmes. Of course, obviously all the gadget geeks will love that sort of thing as well!”

Hot fill is something that used to be commonplace in the UK. However it is perhaps a feature that is beneficial to UK users, but has been lost in the move to globalisation. In general manufacturers would rather make as few models as possible, so having cold fill only models are suitable for the global market. Here in the UK 80% of us heat our water using gas, which is approximately a third cheaper than electric heating, so it is actually cheaper to use domestic hot water than it is to use a washing machine’s electric heater. If household water is heated electrically or even by solar heating, where hot water is essentially free, then it makes less sense to have the dual fill option. For the rest of us, dual fill is a more energy efficient way of heating the water in the first place and also allows shorter, less energy consuming, washing cycles. Ebac claims the cost of installing a hot water feed would be ‘in the region of a tenner’ and would rapidly be recovered by reduced operating costs.

"Ever since I developed our very first industrial dehumidifier when the business was founded, I've strived to retain a culture that is continuously challenging the norm. We think differently about all aspects of the business and never accept that there isn't a better way to do something.” - John M Elliott MBE, DL |

Putting together a design team to develop the new range was largely taken from the existing in-house resources that had worked on the dehumidifiers and water coolers, although an additional designer was employed specifically to design the fabrication. The design team is made up of six design engineers and five technical support engineers. “The electronics and oscillating group expertise was bought in but apart from that we did most of it ourselves,” said Petty. “It maybe took us longer, but I do think that sometimes with a clean sheet of paper, you’re not burdened with kind of legacies of how things have been done in the past. Although we did re-engineer a lot, we stripped down a lot of washing machines in this project. The heart of the design is ours but we don't constrain ourselves if we don't have the expertise.”

The same is true for the manufacturing strategy. Petty said: “It's a bit of a mix really. We make the casing and drum from scratch as we do all of the plastic components. But we don't make the motor or the valves, nor do we make the glass door or the concrete weights. We don't have a hard and fast rule about what we buy or make - we make the right commercial decisions for each individual project.”

The focus during the whole design process has been to obviously meet washing standards but also to meet the customer needs that were raised during the research programme, making washing easier and the machines last longer – most come with a five year guarantee. Petty observed: “Most of these features are very simple but because we use them every time we wash they have a lot of value to those using them. Things like a liquid boat that keeps the detergent safe until the wash cycle when you need to pre-wash muddy clothes. A siphon to drain the tub when you need to clean the filter. A quick release button to remove the drawer for easier cleaning. Simpler dial and wash programmes. Our philosophy has been to save money, save time, make the laundry easier and give peace of mind with a good warranty - we call it washology.”

The biggest challenge for Ebac has been getting to grips with the testing standards and the time it takes to complete tests, something the team completely underestimated. In fact the launch of the machines, which had been intended to be this year is now planned for spring 2016, although some machines may be available in advance of the official launch. Petty explained the reason for the delay: “During testing we found an opportunity to improve the durability of a component and have now redesigned that part of the oscillating group. Unfortunately this means a tool modification that will take weeks and then we'll have to test again - just to be sure that we haven't made a change that has an impact elsewhere. We took the decision to delay the project and not risk a bad start.”

So does progress at Ebac represent a bounce back for British industry, will the company pave the way for others? “I hope so, but I think it’s about thinking differently,” concluded Petty. “Whether we’ll ever attract the big brands back with the big factories, I’m not so sure. But I think when we look at things on a slightly smaller scale, and concentrate on that local market as well and what people want out of a product, rather than trying to have a one size fits all, then I can’t see why that more can’t follow.”