‘Flow forming’ shapes a metal element in a single step. A 43cm-diameter aluminium tube forming part of the upper stage of a research rocket, made by metal forming, was put to the test recently at NASA’s Wallops Flight Facility on a suborbital mission lasting nine minutes.

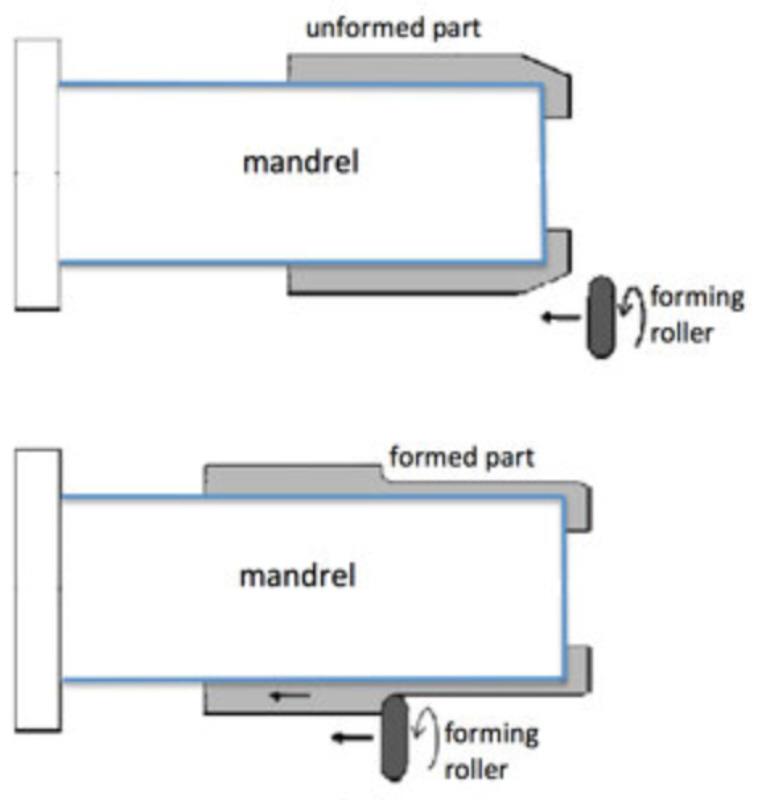

Metal flow forming (left) has so far been used to make complex parts only a few centimetres across. The challenge for launch vehicles is to adapt the technique to produce large single-piece elements such as cryogenic tanks or the structures that connect rocket stages.

The required diameter varies depending on the vehicle, from 3m for launchers like Vega, Ariane and Falcon to 8m for NASA’s large Space Launcher System.

Unlike traditional methods that involve multiple steps, many welds, time and expensive jigs and tools, flow forming requires no welds for a tube and perhaps one or two for a cryotank. The weight is optimised and cost reduced through a shorter production time. It is also better for the environment because it saves energy and there is no waste material.

To date, 15 stiffened aluminium tubes (right) of 0.5m diameter have been built, demonstrating that this is a reliable method for creating structures with larger diameters.

“We are confident that we can build structures with diameters of 3 to 8m and higher, with complex shapes,” commented Adriana Sirbi, ESA’s project manager. “In the future, we wish to produce a stiffened cryogenic tank with tank domes.

“The results from these tests have moved us closer to that goal.”