On their own, this is very impressive. However, these features and capabilities are not developed in isolation. They are developed as part of a cohesive strategy to deliver integrated technology that impacts not only your experience with our software, but also provides a solution to your product development goals.

So for this post, I thought it would be useful to step back and, in the spirit of 10X, consider ten of these features and capabilities that holistically make an impact on aerospace simulation. (I should stress that the order is not a reflection of importance or relevance, simply a grouping in terms of industry initiatives.)

One of the primary trends impacting the industry in recent years has been the rising cost of fuel. This squeezes the margins of the airline industry and while the oil price today is at low levels not seen for many years, the trend still holds over the 25-plus year life span of an aircraft. This means the industry is still keenly focused on initiatives that reduce the cost of flight. So what capabilities of ANSYS 17.0 help?

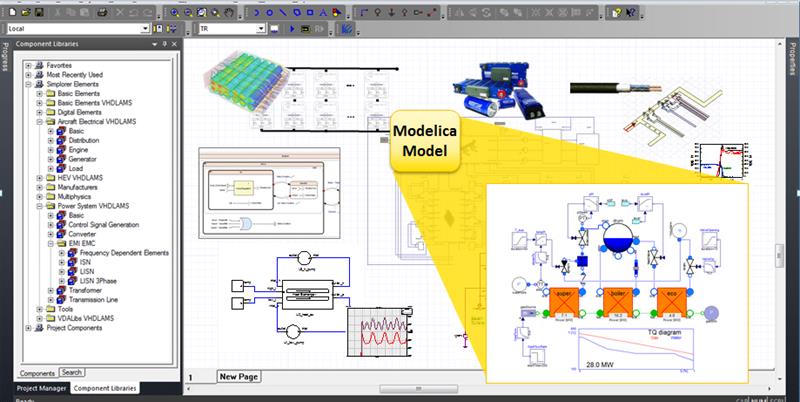

First, we have delivered an increase in speed for system level solutions and second, we now have native support for Modelica libraries. What does this mean? Well, to develop truly efficient aircraft designs it is necessary to study the whole system, not just optimise individual components that, when assembled, deliver a suboptimal system. These two features enable aerospace engineers to increase their productivity for system verification.

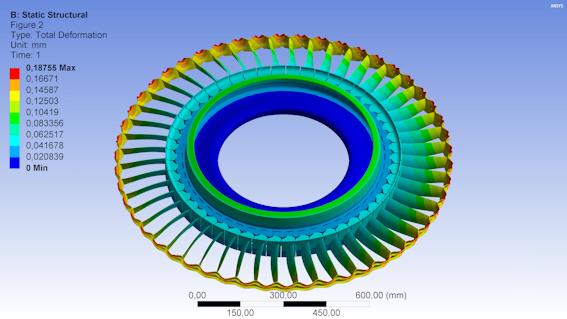

To deliver a more efficient aircraft, you also need to reduce the weight of the aerostructure. This means understanding the behaviour of advanced materials such as composites and new manufacturing techniques such as additive manufacturing. Both aspects rely on the ability to accurately and rapidly perform aerostructure analysis. So our third new feature is a step change in the parallel scalability of structural simulation.

The fourth new feature is the new ANSYS composite cure simulation capability that enables engineers to understand the impact of composite manufacture on the final shape of the part. This is critical for cost-effective aerostructure component integration. We recently gave a webinar, with Aviation Week, on just this topic.

The fifth feature is the significantly improved workflow for ANSYS CFD. Even small changes in aerodynamic performance can have a significant impact on the lifecycle cost of an aircraft, and computational fluid dynamics (CFD) is a mainstay of aircraft design today. Not only does the improved workflow enable faster, more accurate CFD analysis, but the parallel scalability I mentioned earlier accelerates the process even further. Allowing larger and more complex systems to be analysed efficiently. That brings me to feature number six, better, faster CFD — we have broken the world record for parallel computation scaling.

Of course, the biggest impact on aircraft fuel efficiency and environmental impact can be made through continuous improvement of the propulsion system. A quick search of publications in leading journals and conferences will inform you that ANSYS simulation tools are a core component of the leading aircraft engine manufacturers’ design process. ANSYS 17.0 has delivered a rich suite of enhancements for turbomachinery design. Representing the seventh and eighth advances, I’d like to highlight improvements in the speed and accuracy of combustion modelling and the dramatic speed up of blade row simulation.

We know that the industry is not just about delivering the most efficient aircraft. Ensuring the safety of passengers is critical and at the forefront of all aerospace engineers’ minds. In late 2014, the FAA updated the regulations for icing in terms of supercooled large droplets. A few months later, in early 2015, ANSYS acquired the assets of Newmerical Technologies International and their industry-leading icing simulation tool. At number nine, I am pleased to say that ANSYS 17.0 integrates a highly validated aircraft and aircraft engine icing simulation tool with the ANSYS Workbench simulation platform.

And finally, our tenth advancement: As news headlines surrounding the F-35 Joint Strike Fighter continue to remind us, verification and validation of aircraft control and display software continues to be a critical path design item. ANSYS 17.0 includes a number of out-of-the-box templates for a range of software standards that make it even easier to automatically generate safety-critical embedded software.

Thanks for sticking with me to the end. If you’d like to learn more, I will be reviewing these ten features in a free webinar at 9am Eastern and 4pm Eastern on March 23rd where we will also take a deeper dive into the topics of icing and composites curing. I hope that when you place these ten exciting new features and capabilities in the context of the aerospace industry’s key business initiatives, you will see that the sum is indeed greater that the parts.