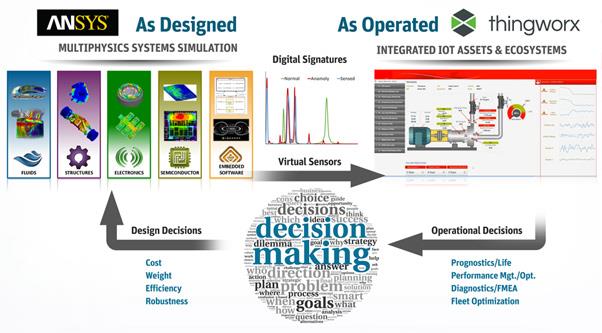

"Companies can use digital twins to detect and isolate faults, perform diagnostics and troubleshooting, recommend corrective action, determine the ideal maintenance schedule, optimise asset operation, and generate insights to improve the next generation of the product."

Companies that leverage simulation during the product development process have dramatically improved product performance, reduced engineering and manufacturing costs, and delivered their products to market more quickly. The Internet of Things (IoT) is now making it possible to capture real-time data about an operational product and integrate it with the organisation's digital information about the product, including simulation models, to optimise the current state of the product or asset. This is called a digital twin of the product. The example of a pump typically used in process plants shows how a digital twin processes sensor data generated from an instrumented asset and leverages simulation to predict failures and diagnose inefficiencies. This enables an organisation to take action to immediately correct problems and optimise the asset's performance.

Operational data and interface

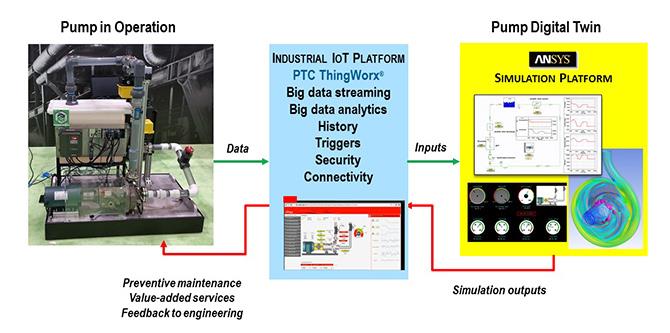

The pump was equipped with pressure sensors at its inlet and outlet, accelerometers on pump and bearing housings to measure vibration, and flow meters on its discharge side. An actuator controlled the discharge valve while the valve on the suction side was manually controlled. The sensors and actuators were connected to a data-acquisition device that sampled the data at 20 KHz and fed it to a Hewlett-Packard Enterprise (HPE) IoT EL20 edge computing system. The PTC ThingWorx platform created an ecosystem to connect devices and sensors to the IoT, reveal the value of IoT data, develop enterprise-level IoT applications, and empower end users through augmented reality. ThingWorx was used as the gateway between the sensors and the digital data, including the simulation model of the pump. A machine-learning layer in ThingWorx running on the EL20 monitored the sensors and other devices, automatically learning the normal state pattern of the pump in operation, identifying operational anomalies, and generating insights and predictions.

The ThingWorx platform was also used to create a web application that displays sensor and control data as well as analytics. For example, the app displayed inlet and outlet pressure, and predicted bearing life. An augmented-reality front-end superimposed sensor data and analytics as well as parts lists, repair instructions and other persona-based information on an image of the pump seen through a user's smartphone, tablet or smart glasses.

The real pump connects to its digital twin using ThingWorx.

Simulation: The "secret sauce" of the digital twin

The team from ANSYS built a reduced-order, system-level model of the pump using ANSYS Simplorer design software running on the HPE edge computer. The system model connects to sensor data through PTC ThingWorx and mimics the hydraulic system's operation. The system model also connects to a human–machine interface (HMI) developed using ANSYS SCADE software with the same gauges and dials as the physical pump. With this configuration, the system model can be disconnected from the physical pump and operated offline to explore proposed operating scenarios.

The system model could also be instrumented using virtual sensors to measure, for example, pressure downstream and upstream of the valves. ANSYS developed a detailed 3D computational fluid dynamic (CFD) model of the pump that runs in the cloud and links to data coming from the asset (if online) or the system model (if offline). Along with being the source for pump performance curves used for rapid systems-level simulations, this 3D model is the basis for more-detailed interrogation and diagnostics of off-design operation and performance assessment in anomalous conditions.

A Flowserve pump highlights the benefits of a digital twin.

"The technologies that underpin the IoT make it possible to integrate simulation with products as they exist and operate in the real world."

Delivering insight

To demonstrate the value of the digital twin, the pump initially was operated normally. An anomaly was manually introduced by closing the suction valve to 50%. The sensor readings showed that the suction pressure, discharge pressure and flow rate decreased drastically, while the accelerometers showed high levels of vibration. Red alerts were issued, and the predictive analytics indicated that the projected life of the pump bearing dropped to only a few days if this condition persisted. But the sensor readings and analytics did not explain the effect of anomalous flow conditions on the pump's operation, why the pump was vibrating or what possible solutions could be considered.

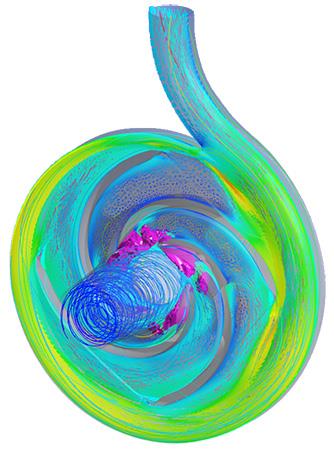

The connected system model showed the same HMI readings as the physical pump, with reduced inlet pressure, outlet pressure and flow rate. To understand the root cause and provide insight on exactly why the vibrations occurred and what the effect was of the change of flow condition on pump operation, a 3D simulation model in the cloud connected to the physical pump was triggered by activating a "3D simulate" button on the system model HMI. The 3D simulation showed that the drop in pressure inside the pump caused cavitation, forming vapor bubbles. In the pump's higher pressure regions, bubbles imploded and generated vibration.

A 3D simulation model shows that cavitation, as visualised by the purple vapor bubbles, is the effect of a faulty valve and the cause of a vibration problem.

By disconnecting the system model from the physical pump, the system model's HMI could be used to try various potential fixes. For example, the system model predicted that opening the inlet valve would solve the problem. To validate this potential fix, a second 3D simulation was performed on the offline system model with the opened valve. The 3D results showed no vapor bubbles. The fix was implemented by opening the inlet valve on the physical pump, and performance returned to normal.

The IoT allows simulation models to connect to operating products using a platform like ThingWorx so that industry can better understand and optimize product performance. Companies can use these digital twins to detect and isolate faults, perform diagnostics and troubleshooting, recommend corrective action, determine the ideal maintenance schedule based on the specifics of the individual asset, optimise asset operation and generate insights that can improve the product's next generation. The potential benefits of digital twins are significant. The low-hanging fruit is in optimising maintenance and operational troubleshooting. But as customers begin to demand outcomes and not just products, the digital twin has the potential to be the key to unlocking this additional value for both product manufacturers and their customers.