The team has demonstrated its technique by printing a ‘living tattoo’ — a thin, transparent patch patterned with live bacteria cells in the shape of a tree. Each branch of the tree is lined with cells sensitive to a different chemical or molecular compound. When the patch is adhered to skin that has been exposed to the same compounds, corresponding regions of the tree light up in response.

The researchers, led by professor Xuanhe Zhao from MIT’s Department of Mechanical Engineering, and associate professor Timothy Lu, say that their technique can be used to fabricate ‘active’ materials for wearable sensors and interactive displays. Such materials can be patterned with live cells engineered to sense environmental chemicals and pollutants as well as changes in pH and temperature.

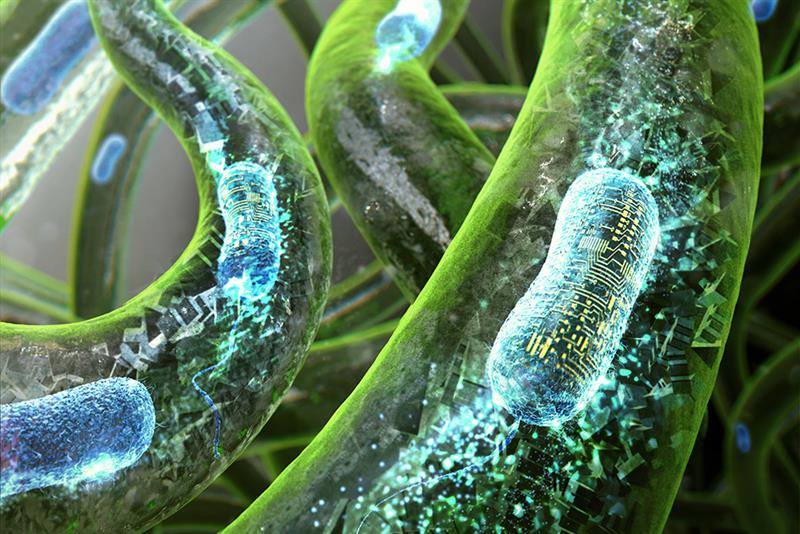

The researchers say the technique could be used to print ‘living computers’ — structures with multiple types of cells that communicate with each other, passing signals back and forth, much like transistors on a microchip.

The researchers say the technique could be used to print ‘living computers’ — structures with multiple types of cells that communicate with each other, passing signals back and forth, much like transistors on a microchip.

For more near-term applications, the researchers are aiming to fabricate customised sensors, in the form of flexible patches and stickers that could be engineered to detect a variety of chemical and molecular compounds. They also envision their technique could be used to manufacture drug capsules and surgical implants, containing cells engineered to produce compounds such as glucose, to be released therapeutically over time.

“We can use bacterial cells like workers in a 3D factory,” prof Lu said. “They can be engineered to produce drugs within a 3D scaffold, and applications should not be confined to epidermal devices. As long as the fabrication method and approach are viable, applications such as implants and ingestibles should be possible.”