Laser used to process Alumina Ceramic

Alumina ceramic (Al2O3) is used to manufacture many items, including medical prostheses, ballistic armour, laser tubes and circuit boards. Its popularity is due to its strength, durability, corrosion resistance, thermal stability and excellent dielectric properties.

However, these characteristics make Al2O3 difficult to process. The material is prone to cracking from thermal stress and traditional techniques such as diamond grinding can be costly and time consuming.

Rapid technological advances mean it is possible to use Nd:YAG and fibre lasers to achieve a high standard of finish. These lasers are able to provide the necessary levels of control using variable parameters such as spot size, peak power, pulse duration and frequency.

Optimised laser and processing parameters help minimise heat input and significantly reduce the risk of thermal stress which can lead to cracking. Large scattering of the laser beam, which can be seen at some common wavelengths, can be overcome through a combination of high peak power, short pulses and short wavelengths (1µm).

JK Lasers' single mode 200W fibre laser, the JK200FL, has built-in modulation and can achieve good quality cuts of Al2O3 up to 1mm thick. It is possible to achieve pulse widths as short as 5µs by gating at 50kHz which, depending on the purity of the alumina, can provide dramatic improvements to process quality.

The combination of high peak power (10kW), short pulses (15-200µs) and high repetition rate (2000Hz) make this laser well suited to cutting Al2O3 up to 2mm thick. It is possible to cut up to 3mm with multi-passing.

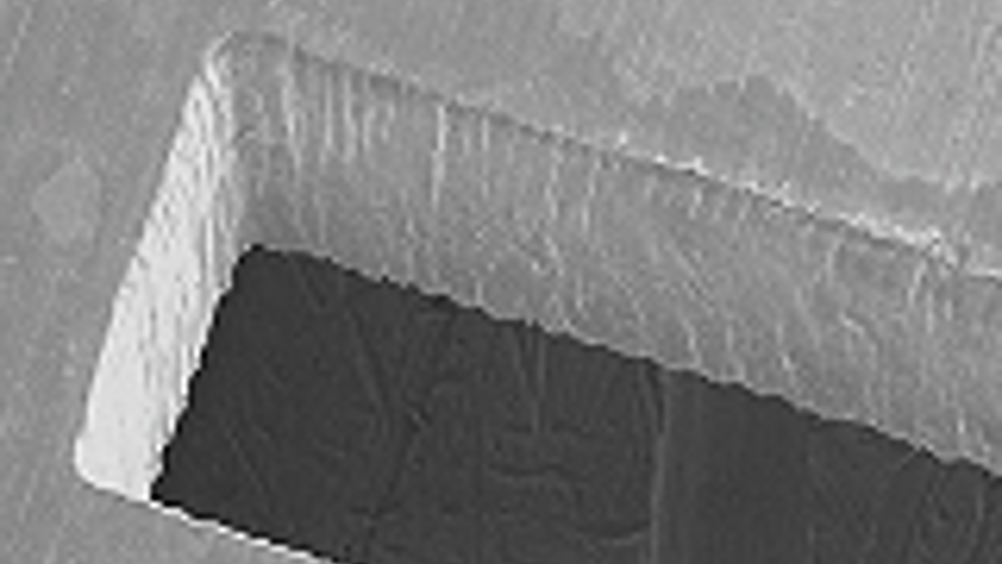

The results demonstrate that both JK Lasers' SM fibre lasers and lamp pumped pulsed Nd:YAG lasers can machine Al2O3 between 96 and 99.7% purity. With no evidence of micro-cracking or dross along the cut edge, JK Lasers' say its range of fibre and Nd:YAG lasers offer manufacturers a viable alternative to traditional processing techniques.

JK Lasers manufactures Watt to kiloWatt fibre lasers, continuous wave and pulsed Nd:YAG lasers, bespoke process tools and software.