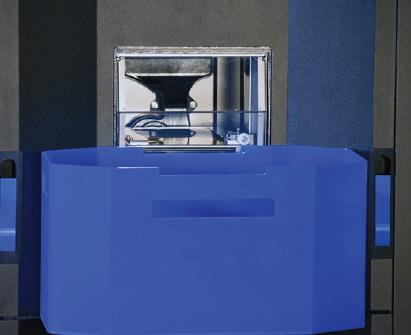

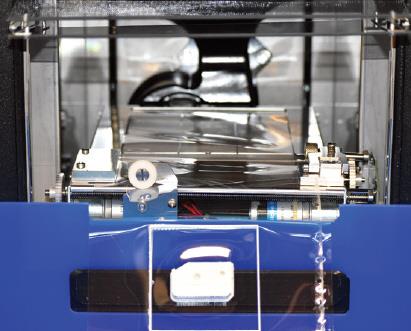

The Stratasys Continuous Build 3D Demonstrator is composed of a modular unit with multiple 3D print cells working simultaneously and driven by a central, cloud-based architecture. The platform is designed to produce parts in a continuous stream with only minor operator intervention, automatically ejecting completed parts and commencing new ones.

Each 3D print cell can produce a different job to help enable mass customisation projects. Additional cells can be added at any time to the scalable platform to increase production capacity as demand requires. Automatic queue management, load balancing and architecture redundancy further lead to accelerated throughput as jobs are automatically routed to available print cells. If a single print cell fails, the job will be automatically rerouted to the next available cell.

Scott Crump, Stratasys co-founder and chief innovation officer, said: “The Stratasys Continuous Build 3D Demonstrator combines our FDM print quality, GrabCAD control and monitoring, and a new multi-cell, scalable architecture to create a breakthrough manufacturing platform.”

Stratasys customers, including Savannah College of Art and Design, In’Tech Industries and FATHOM have begun using the Continuous Build 3D Demonstrator to enhance their offerings and explore new business opportunities. However, commercial availability is yet to be announced.