Learn more about how ALTISS Technologies engineering and metallurgical specialists worked together to create a 2,380bar (34,500psi) and 343°C (650°F ) High Pressure High Temperature (HPHT) Autoclave with a 152mm (6”) bore, which can recreate this extreme environment and put materials to the ultimate test

Achieving The Testing Demands of Ultra HPHT

As easily accessible reserves of hydrocarbons become depleted globally, the energy industry has had to explore ever deeper to locate economically recoverable volumes reserves. In most cases, going deeper means encountering both higher pressures and temperatures in the reservoirs.

In line with these trends the UK Department for Energy and Climate Change coined the term for High Pressure High Temperature (HPHT) over 40 years ago, for wells with bottom hole conditions over 690bar (10,000psi) and 148°C (300°F) and more recently they defined Ultra HPHT (uHPHT) for wells with bottom hole conditions over 862bar (12,500psi) and 166°C (330°F). Operating long term in these conditions alone is challenging enough for many common oil industry materials; adding the presence of common corrosive compounds like Chlorides (Cl), Carbon Dioxide (CO2) and Hydrogen Sulphide (H2S) into the mix means that we need a better understanding of the performance of metals in these environments if we are going to ensure safe long-term operation of these ground-breaking new wells.

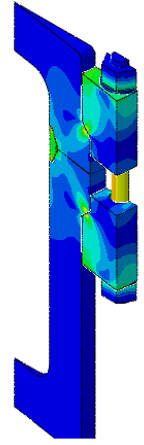

1 - FEA Results from Bolt Pre-Load and Gasket Compression Analysis

1 - FEA Results from Bolt Pre-Load and Gasket Compression Analysis

A Major Downhole Operator needed exactly these questions to be answered in preparation for their future projects, so they approached the ALTISS Technologies team and their unique combination of skills and knowledge to deliver them a fully customized solution. To add yet another twist to this list of challenges – the Operator needed ALTISS to deliver the HPHT autoclave in just eight months – and they did.

The Operator’s specification included:

- 152mm (6”) bore

- 2,380bar (34,500psi) working pressure / 3,450bar (50,000psi) test pressure

- Up to 343°C (650°F) non-uniform temperature distribution

- All metals to meet ISO 15156 / NACE MR 0175

ALTISS Technologies is a specialist energy industry engineering design consultancy and provider of finished products with particular metals expertise in Corrosion Resistant non-ferrous alloys such as Nickel, Titanium and Aluminium. The highly experienced ALTISS design engineers and metallurgists are supported by in-house industry leading Finite Element Analysis (FEA) expertise, delivering a highly optimised design in the shortest possible time.

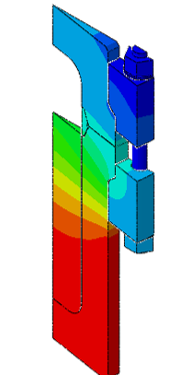

2 – Heat Transfer Gradient Analysis

2 – Heat Transfer Gradient Analysis

The ALTISS team used a structured methodical approach to break down the design tasks to achieve design validation to ASME Section VIII Div 2 as follows:

- Sequentially coupled thermal and non-linear FEA

- Mesh Qualification & Sensitivity Analysis

- Consideration of multiple loading scenarios

- Pressure penetration & sealability evaluation

- Local strain damage evaluation

- Ratcheting analysis and fatigue evaluation

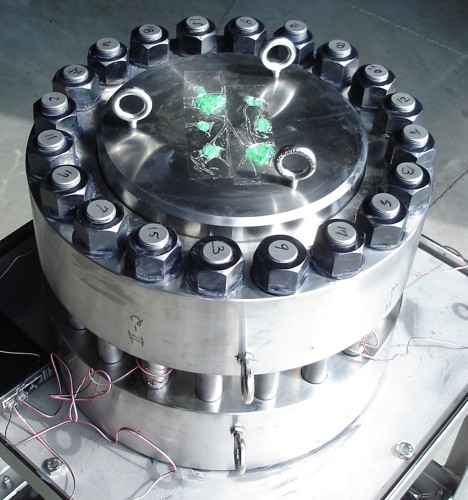

The conclusion of the analysis and engineering effort was a design of HPHT autoclave which was entirely made from titanium and nickel alloys to achieve the complex combination of requirements.

All materials were ISO 15156 / NACE MR 0175 compliant, and the HPHT autoclave used only metal to metal sealing in a fully non-welded design.

3 - HPHT Autoclave, 152mm (6”) bore, 2,380bar (34,500psi), 343°C (650°F), as delivered to the ALTISS Technologies customer.

All the materials were supplied by ALTISS Technologies’ sister company, Titanium Engineers and all machining was completed through ALTISS’ long standing and trusted network of supply chain partners.

The HPHT autoclave passed all its test parameters first time with no deviations and the ALTISS team delivered it in just eight months from customer commitment to final delivery - precisely on schedule and within budget for the customer.

Do you have a challenge for our specialists? Whatever the combination of materials, design and FEA for extremely challenging project work, why not get in touch with ALTISS Technologies. Our expertise is not limited to the energy market – we also work with customers in areas such as Carbon Capture and Storage (CCS), Hydrogen and Geothermal Applications.

You might be surprised at the number of ways our expertise can support your operational, engineering and design needs. Whether you want to work hotter or at high pressures, bend more, reach further or last longer, ALTISS Technologies have the answers.

Go on! Challenge us…