One company, however, has gone further, believing that the use of this technique offers the opportunity for a completely new design paradigm for fluid power components.

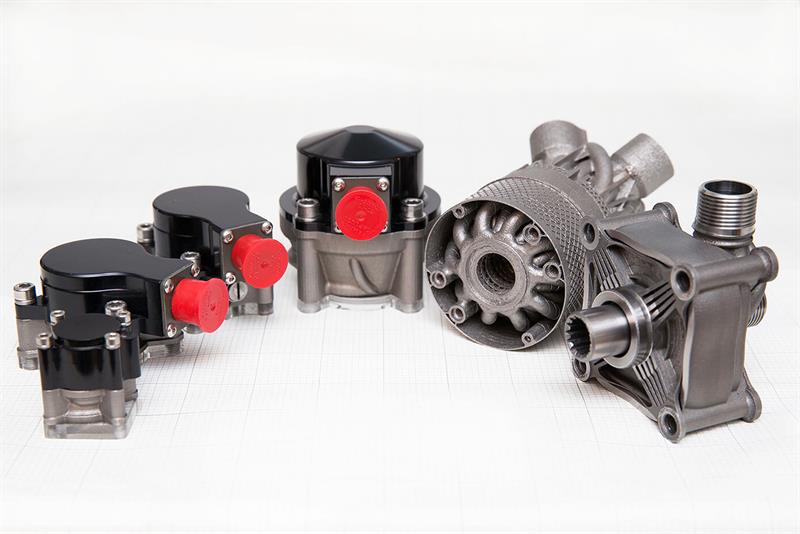

Domin Fluid Power has spent the last few years designing and developing hydraulic products such as valves, pumps and more complex subsystems that are manufactured using metal additive manufacturing (AM) with other techniques for some simple components.

According to Marcus Pont, general manager of Domin Fluid Power, this new design paradigm allows the engineer to rid themselves of the constraints of subtractive machining and open their eyes to the brave new world of metal AM.

He believes that this technology creates two big step changes in how fluid power products are designed.The first, he says, is that, rather than simply tweaking existing designs, it means that products and components need to be designed from first principles. He says: “Crucially we are trying to design complete products and systems from the ground up rather than focusing on component optimisation…If you don’t start from first principles based on the manufacturing method, you end up with something that’s not right for older methods or for the methods that are there now.”

He continues: “If one starts off tentatively and redesigns a pipe that turns a 90º corner, while there is an obvious benefit to pressure drop in that pipe, the product will remain relatively unchanged. Is the small benefit worth the potentially large increase in cost? Or should one think big and go back to first principles to try and redesign a complex fluid power product that has remained largely unchanged for decades? Historically when a new material/manufacturing paradigm comes along, there is a period of time when people apply the new paradigm to an old design. We are looking to change that now.”

He continues: “If one starts off tentatively and redesigns a pipe that turns a 90º corner, while there is an obvious benefit to pressure drop in that pipe, the product will remain relatively unchanged. Is the small benefit worth the potentially large increase in cost? Or should one think big and go back to first principles to try and redesign a complex fluid power product that has remained largely unchanged for decades? Historically when a new material/manufacturing paradigm comes along, there is a period of time when people apply the new paradigm to an old design. We are looking to change that now.”

The analogy he offers is of Sir Thomas Telford’s iron bridge in Ironbridge, Shrophire. “When you look at that, you see a bridge that is made of iron, but looks like it’s made of wood because the engineer didn’t yet appreciate the ways in which the new technology could transform design principles. As we see it, that’s still the case for a lot of engineers with additive manufacturing. People are often just tinkering with the design rather than taking a holistic view that ensures it makes the most of AM’s capabilities.”

The second change that Pont believes AM is bringing to design is that it is aided by leaving the big decisions to a single lead designer rather than a team of designers with different areas of responsibility. Again, says Pont, this comes down to the need to design differently for the technology. He says: “We find additive manufacturing makes those decisions too complex for those outside the design to offer useful information. Disruptive techniques require the individual engineer to have a much broader skill base.”

Of course, this would seem to fly in the face of modern principles of collaborative design, but Pont feels that designers with responsibilities for different outcomes will often end up pulling in different directions. He says: “Say you have one person responsible for stress analysis and another for weight loss. Weight is directly proportional to cost in AM, while stress is directly proportional to weight. That means there’s no incentive for the two engineers to work in each other’s interests and you end up with a fight between the two rather than a harmonious design.”

Reduced cost is another benefit that Pont believes can be achieved using a ‘first principles’ approach to AM-based design. This may seem counter-intuitive, of course, since few people would naturally associate additive manufacturing with lower costs. “What is the cost of AM?” he asks. “The cost is in the weight of additive you use. The problem we see in the additive world is that people are trying to use the technology to create a value benefit rather than a cost benefit. So they’ll use the design capabilities to cut the component count, but forget that because they’ve used a lot of AM material, they’ve actually increased the cost.”

Reduced cost is another benefit that Pont believes can be achieved using a ‘first principles’ approach to AM-based design. This may seem counter-intuitive, of course, since few people would naturally associate additive manufacturing with lower costs. “What is the cost of AM?” he asks. “The cost is in the weight of additive you use. The problem we see in the additive world is that people are trying to use the technology to create a value benefit rather than a cost benefit. So they’ll use the design capabilities to cut the component count, but forget that because they’ve used a lot of AM material, they’ve actually increased the cost.”

By contrast, he claims, a good, first-principle AM design should use the technology to render the overall design more efficient while remaining cost-effective in its use of materials and processes. “By starting from first principles on one design, we reduced the complex components from 21 to seven, but only one of the components was 3D-printed because it was only there that it brought rewards. By making sure that we don’t use too much of the additive to create the function we need, we can ensure cost-effectiveness. As long as the function achieved is of greater value than the value of the additive material used, we are able to ensure economic viability.”

The fluid power market, Pont believes, is particularly fertile ground for this approach precisely because it has seen relatively few innovatory leaps in recent times. “The fluid power industry has largely remained unchanged for 50 or 60 years – indeed, you could say that it’s been pretty boring,” he says. “What that means is that it’s ripe for innovation in the form of additive manufacturing. However, so far people are just looking at making minor changes to existing ranges of products. That’s understandable, if you have an existing range of products, it’s really expensive to change them to accommodate a new manufacturing method.”

“Where we have an advantage,” he claims, “is that we don’t have an existing range of products in this field, so we were able to start with a completely blank sheet of paper. The result is that our products will look topographically quite different to existing fluid power products, but perform the same function – only more efficiently.”

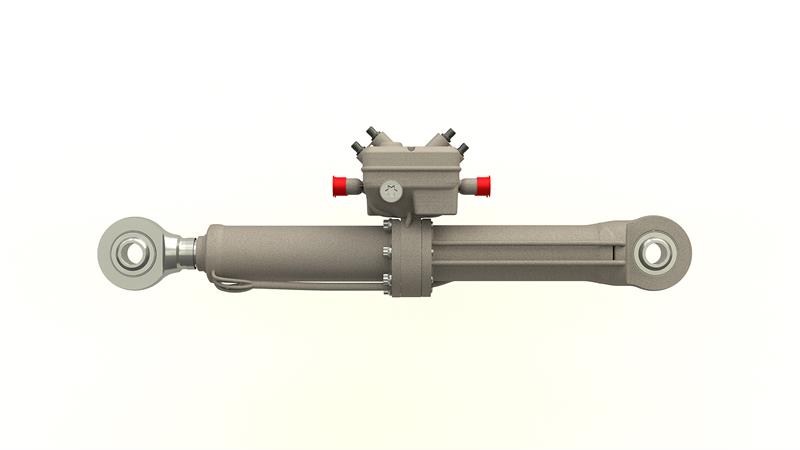

The first product to emerge from this process will be a new servo valve. The L Series Direct Drive Valve, according to Domin, is an innovative step change in performance of direct drive valve technology. Domin claims it offers performance improvements on the current state of the art with respect to response, efficiency and size and weight but can be sold at a highly competitive price. “We believe we have developed a product that has an increase in performance on the current state of the art without having to ask the customer to increase their costs,” says Pont.