JCB’s place in history is the backhoe loader, a truly disruptive technology when it was introduced in 1953. It retains leadership worldwide in this product category and backhoes remain responsible for half of JCB’s business. A trip to the company’s Visitor Centre in Staffordshire reveals that there are many other milestones in its history that have resulted in a diverse product range that tend to more than just the mainstream construction industry.

In fact, there are around 350 products in the range, manufactured at 22 sites across around the world, and each of these products will typically last for around six years before being upgraded. As this is a rolling programme of evolution, it means there are around 55 to 60 product launches per year spawned from 150 – 170 programmes, which themselves each last one to three years. Such evolutions may be needed to meet new emissions legislation requirements, to introduce radical technology updates, or to roll out new features across the range like a new type of cab, transmission or axle.

Despite the diversity in JCB’s products, operators want the same level of convenience and comfort across the breath of the range. So then, why not use the same cab design in a tractor, wheeled loader or excavator, for example?

Innovative designs can be introduced on premium products initially, and then the volume of the backhoe and Loadall (the telescopic handlers) units where, because of economies of scale, the same engineering quality can be introduced at lower costs.

Chief innovation and growth officer at JCB is Tim Burnhope, who said there is a formula for such development: “We use evolution to redesign and develop the product range, but also use an Innovation Checklist, which ensures all of our products right across the world carry the same JCB DNA.”

The checklist includes, among other things, comfort, usability, productivity, cost of ownership, safety, security, quality and reliability – all factors that must be considered with any product development. However, the main theme goes under the label of ‘strength of purpose’. Does it look like it will do, what customers want it to do? For example, does a tractor look strong and fast? Does a mini excavator look simple to use? Does a wheeled loader look robust and powerful?

From evolution to revolution

Every 10 years or so evolution must give way to revolution – a fundamental change to JCB’s product range or to the vital systems within them, for example 10 years ago the 444 DIESELMAX engine.

To speed up the revolution cycle and give the process structure, JCB introduced its Innovation Centre three years ago.

“We say it houses the crazy ones, which is a bit unfair, but what we do is house the people for creative thought for the next projects,” explained Burnhope. “What we realised is we needed an area where we can bring people from anywhere in the business and formulate teams to work on our next revolutionary product designs. Within this centre we have a design studio and advanced engineering research for engineers who work on structures, hydraulics, electronics, electrics… and many of those are in combination, for example, we have an electrohydraulics lab.”

The premise is that evolution happens within the design teams of individual business units, but that is unlikely to foster a fundamental shift in technology.

“When you get the revolutions, quite often we need the people from, say, transmissions working with the Loadall people, working with the electronics people, working with the engine people,” said Burnhope. “So what we’ll do is bring a team of specialist experts from each area, hot desk them, put them together for six months, develop a concept, get it going and then they can go back and introduce it to [individual business units and product designs].”

There is a base staff of more than 100 at the Centre but up to 60 people can be brought in from various parts of the business based on their expertise.

Burnhope continued: “It’s been a real game changer. When you are in a business unit you’ve got to react to the day-to-day. You’ve got programmes to deliver. It’s a very frantic world.

“Evolutionary innovation is relentless. So we pick people out of it and say, ‘don’t worry about the day-to-day. You’ve got to worry about tomorrow, you’ve got to think about revolution’. So the minute you walk through the door here, you leave behind everything else and move into a world that allows you to be fully creative.”

This difference in thinking is illustrated by JCB’s drive to improve fuel efficiency over the last five years, which has resulted in a 35% improvement across many of its machines. That well beyond any mere evolutionary tweaks.

Burnhope explained: “I said at the start I wanted it to be 50%. They thought I was completely mad and people thought it should be 10% or 20%. But it caused people to be much more radical in their thinking.”

The Centre includes a ‘rapid factory’ where ideas can be made using 3D printing or more traditional modelling techniques alongside some advanced simulations.

Revolution 1: Backhoe for the city

Having launched the Innovation Centre, JCB needed industry challenges to work on, and three of those have resulted in revolutionary products that have come to market during 2016.

The 3CX Compact for city repair and maintenance

The challenges for the first product were manifold. The main driver was to make a machine that suited one of the busiest markets in Europe – London. Congested narrow city streets and restricted work sites mean that the big machines required to do a job will not fit into the space that is available. The machine in question typically would be a 3CX backhoe loader, JCB’s bestselling product for many years. The result has been a version 35% smaller than its big brother, the 3CX Compact. So how did the Innovation Centre achieve this while maintaining other key parameters like speed and power?

“We break [key parameters of the design] down and put people on different sub-teams,” Burnhope said. “So we say, ‘you go and tell us how to halve the turning circle, how we can shrink the height, or how to get a smaller footprint’. It’s important to do it in different teams because if you just use one team they might continue with a compromise or say they can’t possibly make it 35% smaller. So it causes the teams to go away and be very radical.”

The resulting machine is intended to be a nimble and flexible, but as Burnhope points out, this can place more demands on the technology required.

“If you think about the medical world going to keyhole surgery versus big operations, that’s almost what our customers are looking for,” he said. “We don’t need to move as much material – what we need is to be smaller, and be in and out quicker.”

Revolution 2: Flexible farming

The second challenge came from the agricultural sector. Farmers were looking for more productivity from their telescopic handlers, one of the standard agricultural workhorses. However, the modern farm is not the smallholding of bygone years. Consolidation has meant most farms are of considerable size and moving equipment around represents considerable time lost. How then do you get a machine that is quicker between sites and more productive when it gets there?

Productivity typically comes from the power of the engine supplied with hydrostatic transmission, with the downside that it is cumbersome between sites. Travelling speed, however, is improved by using a good power shift transmission, but on site productivity is then diminished as a trade off.

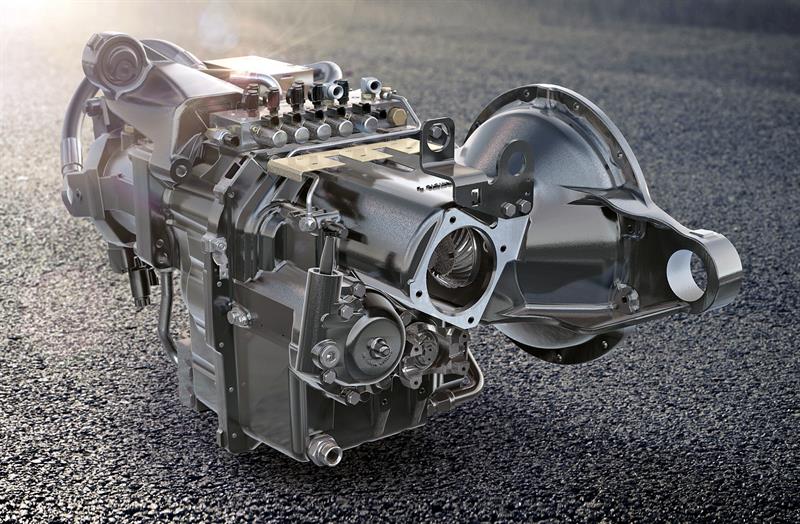

Enter JCB’s Agripro, probably the most innovative of the ‘three revolutions’ on account of its DualTech VT (variable transmission). JCB has the luxury of designing its own transmission and without this ability, this particular development may not have been possible.

DualTech VT brings two different types of gearbox into one. So when operating in a field, collecting hay bales, for example, it will be in hydrostatic mode providing the most productive, fast response, quiet and smooth operation. As it leaves the field and exceeds 19kph it automatically trips to Powershift transmission up to a top speed of 40kph.

Agripo's dual technology

“It’s actually 13% more productive than our current offering, and 25% more productive than any of our competitors’ offerings,” claimed Burnhope.

It is the first time in the sector that two technologies have been squeezed into one gearbox, and it was not easy.

“The big challenge is getting the speeds of the two transmissions to marry, especially on the downshift,” said Burnhope. “If you are at ‘Powershift speeds’ and all of a sudden you brake to 10kph, you’ve got to get the hydrostatic transmission up from 0 to 10 to meet the shift coming down. All that software, and getting that to change seamlessly, with no real feel for the operator probably took us about a year and half to get those shift changes perfect.”

The Agripo has developed a DualTech VT transmission to maximise productivity and speed

Revolution 3: Light heavyweight

The third challenge was to address the construction and development markets instead of lighter-weight repair and maintenance applications.

Burnhope said: “So [our customers] were saying, ‘we want a much smaller machine for certain urban environments, but it’s got to have the capabilities of some of the larger machines’. They told us the big issue was when you sit on these machines and look out, you can only see the horizon. That is a major issue when you work in a city, that you can’t see somebody working in a trench next to you or a pedestrian walking alongside.”

But matching the visibility associated with a mini excavator while reducing the footprint required for urban areas is not easy if you are still trying to maintain the lifting and digging capability of a much bigger machine.

The solution, Hydradig, is a true revolution in that it is a new machine category in its own right claims Burnhope.

Any other equivalent machine has the engine behind the cab and above the slew ring around which the top half of the machine rotates. There are reasons for this concerning tapping services off the engine through the rotating part, but the main reason is that the engine provides a counter balance for the main arm, whether it is being used for lifting, loading or digging.

Visibility is therefore impaired at least in one direction. To solve this one design team came up with the solution of having a cab with perfect visibility in all directions to within 1m around the base of the machine. Obviously this means that the engine and fuel tanks had to go somewhere else.

Looking to its Loadall machines, the team adopted the idea of putting the engine much further down, effectively between the wheels. Although defying convention, reducing counterweight overhang was more than compensated for by lowering the centre of gravity of the machine. In fact, it now has over twice the lifting capacity.

Further benefits are that there is no tail swing, maintenance is easier and by balancing the load across the base the machine it can travel at greater speeds without the ‘nodding’ that other machines experience.

Again, the design process was not conventional. “We simultaneously had our industrial designers, our main design team and some stability experts with us,” said Burnhope. “Even though we were using the same principles of a Loadall, it was a completely different chassis design. We were starting to mock things up. We’d build other models, so some things we built up in wood, some things we’d build in model form and CNC machine to get things to fit.”

Having the ‘services’ on the lower side of the slew ring from where they would be, did present a problem, however.

“I know it sounds daft, but you want to bring somebody else in that is completely creative that’s never worked on slew rings,” said Burnhope. “You’ll find they have got some crazy and completely different ideas, and that’s really where it makes the difference.”

Through these three new products, the Innovation has made a good start and enabled a more creative design process.

Burnhope summed it up: “We are very lucky, we have an entrepreneurial leader in our Chairman Lord Bamford and he continually drives us to find ‘firsts’. He was at the centre of the success of the Hydradig project.

“It’s not about buying innovation - you don’t have to spend millions. The important thing is that you’ve got the right environment, the right people, and the right tools to allow them to be creative. And some of our best innovations have been by far the simplest. It’s having that motivation to find a solution and how you capture it.”

| Tim Burnhope will be speaking about JCB’s design strategy at this year’s Engineering Design Show’s Eureka Conference, held at Coventry’s Ricoh Arena on 19-20 October. For information about the event and to register go to www.engineering-design-show.co.uk |