As major automotive OEMs and new players are launching new electric vehicle (EV) models, adhesives specialist Henkel is leveraging its broad technology base and expertise to drive the transformation from traditional engines to electrified powertrains. The portfolio combines existing and new technologies to enable cost-efficient large-scale assembly and lifetime protection of battery architectures.

Strict regulatory fleet consumption and CO2 emission targets are shaping the challenges of the automotive industry. With hundreds of new EV models being designed and launched at an increasing speed, the integration and protection of batteries and electronic components play a crucial role. With a comprehensive range of technologies and deep know-how tailored to solving these new challenges, Henkel is determined to be the industry’s leading full-solutions partner, supporting its customers from design to integration.

For battery manufacturers in specific, Henkel has identified three major challenges. First, as the value per battery kWh continues to be a significant commercial challenge, materials and adhesives applied in the assembly process of hundreds to thousands of cells in the battery pack need to provide high-speed curing and short cycle times. Second, for operational safety, solutions must comply with thermal management requirements as well as the UL94 flammability standard. Finally, to ensure lifetime performance of EVs, the battery pack housing requires technologies that will allow it to be reopened.

“Our innovative adhesive products and engineering services are playing a major role in optimising the cost-efficient assembly, operational safety and lifetime protection of battery cells,” says Frank Kerstan, director e-Mobility & Powertrain at Henkel. “We are determined to support our customers at the forefront of e-Mobility with a seamless portfolio of technologies as well as application and process know-how for large-scale manufacturing, all available from a single source.

“This is the reason why in 2019 several OEMs are launching a significant number of EV models that have been designed and assembled with Henkel technologies.”

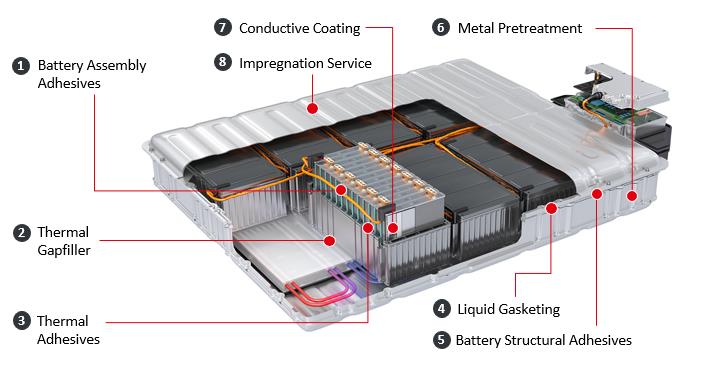

Henkel’s solutions and services are focused on eight integrated key technologies:

Battery Assembly Adhesives:

Henkel offers multiple adhesives that are suitable for large scale assemblies of hundreds and thousands of battery cells. For example, Loctite AA 3525 cures on demand with UV light in less than 15 seconds. Teroson MS 9396 is specialised for battery cell-to-cell bonding and battery case sealing. This modified-silane, easy-to-use one-component technology is environmentally friendly, non-solvent and non-silicone based. With temperature resistance of up to 100°C and an elongation rate of 200% it ensures stable and safe performance of the battery cells.

Thermal Gapfiller:

This thermally conductive silicone-free material with 3 W/mK performs under the harshest environmental conditions. Its cure-in-place kinetics guarantees gap stability and robustness over lifetime. The unique rheology allows extremely fast dispensing for reduced processing times, decreased assembly forces and significant stress relieve for the battery cells and modules. Furthermore, the new filler technology with very low abrasiveness characteristics results in less maintenance to the dispensing equipment.

Thermal Adhesives:

To ensure safe and efficient thermal management of the battery cells and modules, thermal conductive adhesives such as Loctite UK 6800 and Loctite EA 9794 allow efficient heat transfer to cooling plates. This two-component polyurethane technology has a thermal conductivity of 1.9 W/mK. To overcome different coefficients of thermal expansion, it also offers excellent adhesion on different substrates with a shear strength of >10 MPa and an elongation of 44%.

Liquid Gasketing:

Henkel also provides numerous solutions to prevent leakages and variations in temperature within the battery pack housing. To meet the UL94 flammability standard, Teroson MS 939 FR has proven to be a reliable and high-performance technology. Likewise, Loctite SI 5970 acts as a custom-fit solution when it comes to resistance against oils and other automotive fluids. For the challenge of serviceability, Loctite AA 5884 (Asia: 5883) is a fast, UV light curing polyacrylate technology that provides sealing reliability by compression while allowing the battery pack housing to be reopened for repair.

Battery Structural Adhesives:

The structural integrity of a battery pack is relevant for dynamic load cases and crash performance. Henkel offers high-strength adhesives for aluminium and multi-metal battery frames with two-component epoxy products like Teroson EP 5065 or Loctite EA 9466.

Metal Pre-treatment:

In the light of commercial challenges, Henkel surface technologies reduce process and maintenance costs resulting from reduced energy and water consumption. Battery housings, typically constructed of aluminium, need to be pre-treated in a cost-efficient way before painting. Henkel offers a variety of OEM approved processes: Bonderite M-NT 400, Bonderite M-NT 160 / 161 and Bonderite M-NT 5200. For mixed-metal applications, the Bonderite 2-step process allows energy savings and a reduction of process sludge.

Conductive Coating:

Another key challenge for market success is to improve the charging and discharging performance of lithium-ion battery cells. Henkel has developed conductive coatings to overcome the weakness of the interface at the aluminium cathode. The technologies of Bonderite L-GP EB 012 and Bonderite S-FN 15000 lower the internal electrical resistance and increase the adhesion of the active material to the cathode for Lithium Iron Phosphate (LFP) and Lithium Nickel Manganese Cobalt (NMC) battery cells.

Impregnation Service:

Henkel’s Loctite Impregnation Solutions (LIS) service leverages the flowability of low-viscosity polymeric resins to fill micro-porosities and voids (‘leakers’) and permanently seal components, such as aluminium casted battery housings.