There is a sector, albeit a small sector, of the buying public who watches cost more than most people's cars, their cars are worth more than the average house, and the value of their houses doesn't bear thinking about.

When everything else in these people's lives exudes quality and exclusivity, why would they be happy with the same mobile phone used by the rest of the population? On such a philosophy Vertu has built its business, designing, manufacturing and supplying exotic phones – backed by a personal service – from its base in Hampshire.

The phones are hand crafted and signed by the craftsperson who assembled it. Entry level is the Vertu Aster range, starting at £4200, but the cost of the phone is essentially determined by the materials used in its construction. And there is no upper limit. If snakeskin or diamonds is your preference it can be done but the price tag will be adjusted accordingly.

These phones are not gimmicks though. Hutch Hutchinson, head of design at Vertu, said: "Most of the time, good luxury is engineering.Rolls-Royce didn't set out to build a jewel-like trinket of a car.They set out to build a car that would go round and round and round Brooklands with utter reliability, because that really was what luxury meant."

For example, the processing heart of the phone is the high-performance Qualcomm Snapdragon quad core processor, the audio performance is tuned and tested with Bang & Olufsen, and the camera comes from Hasselblad and features a 13 megapixel sensor, dual LED flash and a lens of virtually scratch-proof sapphire crystal. Even the ring tones were exclusively recorded for Vertu by the London Symphony Orchestra.

It is a case of using outsourcing strategically to get the best results. Neil Hooper, VP of R&D souricng and quality, said: "What we're trying to do is keep our core competencies in-house and used the best team in the world to do it.We're not the best in the world at assembling circuit boards with micro BGAs, so we use partners to do that and focus on where we do see we can add value. This is in the home crafting, the components where we can do things better, and the audio - it's not just about the components we use, it's about the audio cavity, the way you see the cavity, the way you model that cavity to make sure it gives you the bass and the best response."

Clearly getting the design environment right is crucial, but the company found itself in an interesting position three years ago when the apron strings were being cut by its parent company, Nokia. Tim Draper, CAD manager, commented: "It started in 2012 when Nokia made the strategic decision to divest Vertu. We entirely reliant on Nokia for everything really, in terms of IT infrastructure, the software that it used to develop new products."

That software was intended to be Catia V6, for although Nokia were to remove themselves completely from the management of Vertu, it had negotiated a deal for the use of Catia V6, which was to be its own way forward. However, a the time the company was still using Catia V5 without any migration to the new platform. Draper said: "The challenge set to me was to migrate Vertu to standalone V6 environment in six months. It was an almost impossible challenge to take a company, do all the infrastructure and transport everybody over to a new system and be productive without interrupting what we were already doing in six months." So what Vertu did was negotiate a deal that allowed continued use of Catia V5 whilst conducting a properly managed transition to V6. It was a break that allowed the company to re-evaluate what it actually needed. "

It became clear to us during 2012 that moving to Catia V6 may not be the best way for us," continued draper. "We struggled to make that system work with the way that we would run the business.We were also facing a brand new challenge, and that was actually re-structuring the way that we worked and the way that we developed the product to suit the new Vertu, and this is a Vertu who weren't buying technology, or weren't being provided with technology by Nokia anymore."

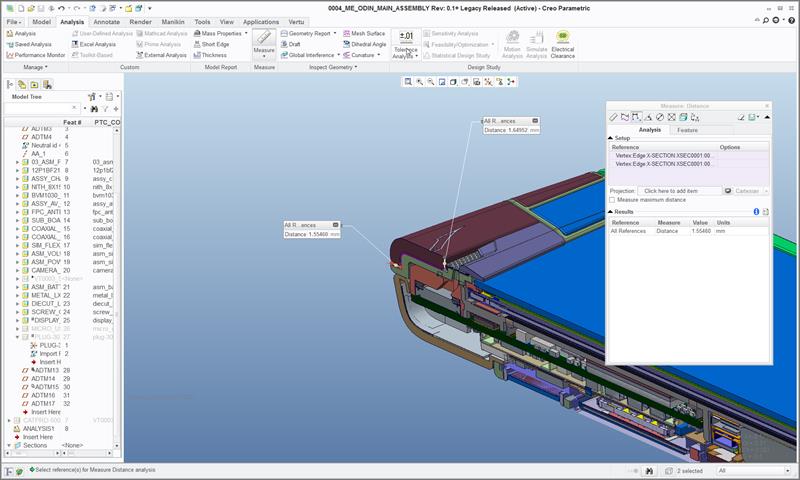

The company was moving towards an Android platform and the engine room – the electronics – also had to be designed from the ground up rather than being supplied by Nokia. There was also the issue of developing a supply chain with a small number of key collaboration companies who were going to work jointly with Vertu to develop this new product. So when Vertu was faced with teh possiblitiy of moving away from its Nokia imposed CAD environment, there was one over-riding consideration. Draper said: "Today actually there's no difference [between CAD packages] in terms of their overall capabilities, but for us the key thing was we needed something that helped us get locked in and plugged into that supply chain. We did a quick survey that revealed 100% of our key collaboration partners were all using PTC Creo."

|

What the team really needed was the collaboration element and this became the key benchmark when choosing the system. "PTC basically sat in with us and showed us how all that could be done - simulating how the collaboration process, being able to partition work packages and bring them back into the system.What we essentially had with Windchill [PTC's PLM product] we found was everything we liked about the old PDM system but with a load of new functionality."

From the decision to move from PTC in June 2013, it only took until the end of that year to get the first full project underway in the PTC. Draper said: "We had our key collaboration partner working within that project with us and the time we saved was huge.Previously we were swapping STEP files twice a week, and every time we swapped step files you get a completely new representation of your partner's data.So you have to integrate that into your own model.You don't know what's changed, you have to check everything, and we were doing that twice a week here, and it was being done the other end as well." Now all 45 CAD seats and 170 PDM users have switched to the new platforms.

The result is that Vertu have created the right environment for creating the right products for its customers and the first products are arriving. Draper said: "One year after starting our first project in Creo, I held that phone in my hand.It's not botched, it's not in the public domain, but I have held that phone as a working phone in my hand, which is a pretty good achievement given that we switched CAD systems and everyone needed to learn a new system."

"Most of the time, good luxury is engineering."

"Most of the time, good luxury is engineering."