At the end of the day, though, robots are collections of components and, of these components, some of the most crucial are bearings. However, robotics presents particular challenges in terms of bearings.

Thin section bearings deliver higher speed, improved efficiency, and high levels of accuracy as well as reduced friction and impressive design flexibility. Because there is very little difference in size between the internal and external ring, they also reduce the weight and bulk of an application, making them an ideal choice for robotics, where both footprint and weight are premium items.

However, because they are so thin, it is necessary to pay particular attention to the roundness of the ring itself. If you take a thin section bearing without any lubricant and spin the inner ring, a light squeeze of the outer ring between finger and thumb will stop the bearing in its tracks, thanks to the high level of flex in the device.

As a result, the manufacturing process has to be extremely precise to ensure the highest possible degree of roundness in both rings, as well as good noise levels in the bearing itself.This will normally call for fine grinding and machining, complimented by a very high level of quality in both the process and the raw materials. If the rings are not perfectly formed, even a minute discrepancy will stop the bearing running as smoothly, producing excess noise.

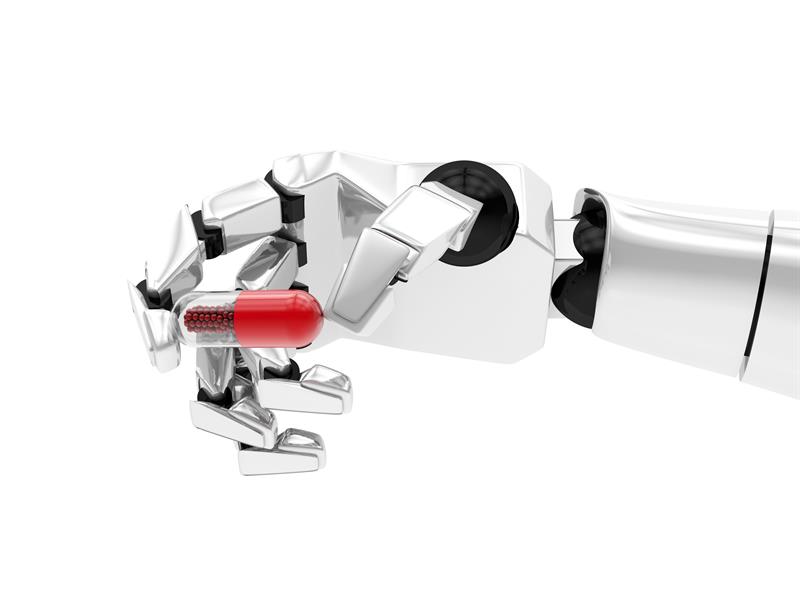

Grasping is a particular problem for many industries. Not just picking up an object — but grasping it well and ensuring that each grasp is correct for the object that’s being picked. “More and more I’ve had people come up to me asking how we can improve robotic grasping,” said Rich Walker, managing director at The Shadow Robot Company. “The market is pushing us to improve the technology.” Standard industrial grippers are built to pick up one thing, move it and put it down. If you have two different sets of objects, you’ll need two different grippers to perform the task. Modern manufacturers are increasingly diverse, producing reams of different products, often with custom finishes.

Grasping is a particular problem for many industries. Not just picking up an object — but grasping it well and ensuring that each grasp is correct for the object that’s being picked. “More and more I’ve had people come up to me asking how we can improve robotic grasping,” said Rich Walker, managing director at The Shadow Robot Company. “The market is pushing us to improve the technology.” Standard industrial grippers are built to pick up one thing, move it and put it down. If you have two different sets of objects, you’ll need two different grippers to perform the task. Modern manufacturers are increasingly diverse, producing reams of different products, often with custom finishes.

Single-use tooling is no longer sufficient to keep up with demand. There is a need for tooling that is easily adaptable to pick up many different types of objects. The robot engineers at the Shadow Robot Company have had plenty of experience manufacturing dextrous robotic hands for academia and nimble work, but this type of robot isn’t suitable for industrial applications. Instead, they looked to create a robust and reliable Smart Grasping System, with the intelligence to recognise many different objects and select the appropriate grasp.

As part of the design process, the Shadow Robot Company needed specific bearings with very tight tolerances in dimensional accuracy. This is important for ease of installation and accuracy of the smart grasper’s movements. So, the team contacted SMB Bearings as the business is well known for consistency and vast supply of non-standard bearings. Based on the requirements of this particular project, SMB Bearings recommended and supplied EZO thin-type precision bearings.

With the support of SMB Bearings and using a small sample of the EZO thin-type precision bearings, the research and development team at the Shadow Robot Company trialled different grease levels to find theoptimal grease fill. As robotic movements need to be predictable and accurate some friction is essential to ensure this control. A process of testing and trial and error demonstrated the correct friction coefficient and its corresponding percentage grease fill for optimum performance.

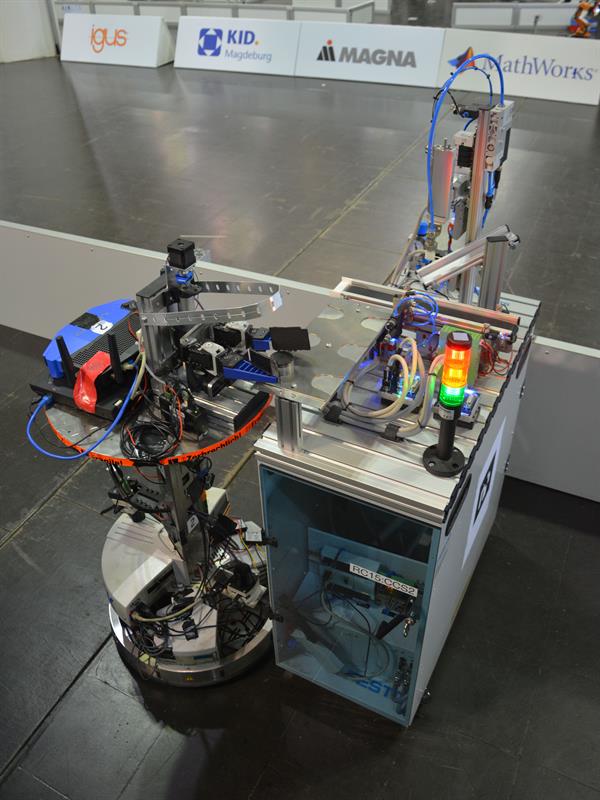

Another bearings supplier seeking to solve problems in the robotics sphere is igus. The results could be seen in the robots from 14 countries that competed against each other at the recent RoboCup German Open 2018 in Magdeburg. In the logistics league, the Carologistics team from Aachen became German champions - with the support of the motion plastics specialist igus.

Pupils and young engineers from around 40 universities and research institutes had a wide variety of robots in their backpacks: from small humanoid robots to table-high transport robots. They competed in various disciplines, such as football, simulated rescue missions or intralogistics tasks.

A large number of the teams use self-lubricating and maintenance-free high-performance plastics from igus in the moving parts of their robots. Team Carologistics, sponsored by igus, is one of them, achieving first place in the logistics league. Operating in a Smart Factory environment, the robots communicated with each other and oriented themselves in a 112m2 field without help. They transported rings and caps between assembly stations and assembled products at the end.

In the new intralogistics robots, drylin linear modules are now used in the three-axis control of the gripper. In addition, an electric linear axis with a spindle motor and a dryspin leadscrew, which ensures precision when placing and removing the products. In the Standard League, in which robots compete on the football field, igus also supported Team B-Human of the University of Bremen and the German Research Centre for Artificial Intelligence.

SKF adds bearing analysis software SKF has added an easier and faster bearing evaluation tool to its shaft analysis software portfolio. SKF SimPro Quick bridges the gap between SKF’s basic online software tools and its recently released flagship multi-shaft analysis application, SKF SimPro Expert, while maintaining compatibility with SKF’s in-house engineering software. With this comprehensive choice of system modelling and engineering analysis software, SKF is now able to provide its customers with a range of tools that match their individual needs. SKF believes that for the vast majority of its customers, SKF SimPro Quick will provide sufficient power for detailed analyses of single-shaft/multiple bearing systems while being both simple and quick to use. Moreover, customers can make use of SKF SimPro Quick with relatively little effort without having to undergo several days of specialist training. SKF SimPro Quick is a single-shaft/multiple bearing simulation software tool that can quickly evaluate the design of bearing arrangements and their performance, based on customers’ specified application requirements and the conditions under which the bearings will operate. Based on the vast wealth of SKF engineering knowledge, SKF SimPro Quick gives the customer more freedom in their machine design processes and product choices, without necessarily having to consult SKF on bearing selection and shaft configurations. |