Additive manufacturing covers a multitude of processes. Regardless, the notion that you can simply create a 3D design, press the print button and get a perfect 3D model from your printer is not always going to be the case. A particular example is one of the more recent variations of 3D printing – Shaped Metal Deposition (SMD).

SMD is a process that requires heat, and metal can change shape when its temperature changes, so the designer of the printed part not only needs to consider the shape that is printed, but also what shape it will be when it has cooled down. It is not a straightforward task and it is one that has been the focus of a project at the Manufacturing Technology Centre (MTC) in Coventry.

“SMD has multiple advantages over powder-based additive manufacturing technologies,” said Borja Lazaro Toralles, an advanced research engineer at the MTC, with a specialism in simulation and modelling. “Among the benefits of SMD are higher deposition rates, the possibility of building new features based upon pre-existing components, or even the use of multiple materials on the same part.”

Unlike other additive manufacturing techniques that use lasers to melt a thin layer of powder, SMD deposits a sheet of molten metal that is built up layer-by-layer on a surface. It is essentially welding a continuous piece of wire into a certain shape. It is a process that was originally developed by Rolls Royce, but in its formative years SMD was a process that was too difficult to control, requiring a lot of intervention from skilled technicians and the material properties were not well understood.

More recently organisations such as the University of Sheffield’s Advanced Manufacturing Research Centre (AMRC) has progressed the technology to the point where it is commercially viable – offering savings in product lead times, reducing inventories, reducing waste as there is little or no machining needed. This reduces overall cost of manufacturing by an estimated 40%. However, SMD is still a process that can throw up problems.

“One of the challenges of this process is thermal expansion of the molten metal can deform the cladding as it cools, resulting in a final product that is different than what was anticipated,” said Toralles. “In order to predict the outcome of a proposed design, we need either need to minimise the deformations or alter the design to account for them.”

The start of the project looked at a simple rectangular substrate and building a straight wall, which resulted in some distortion in the substrate. The objective was to provide a way of trying to assess how to reduce this without having to make hundreds of experimental examples, with all the associated material, time and associated cost.

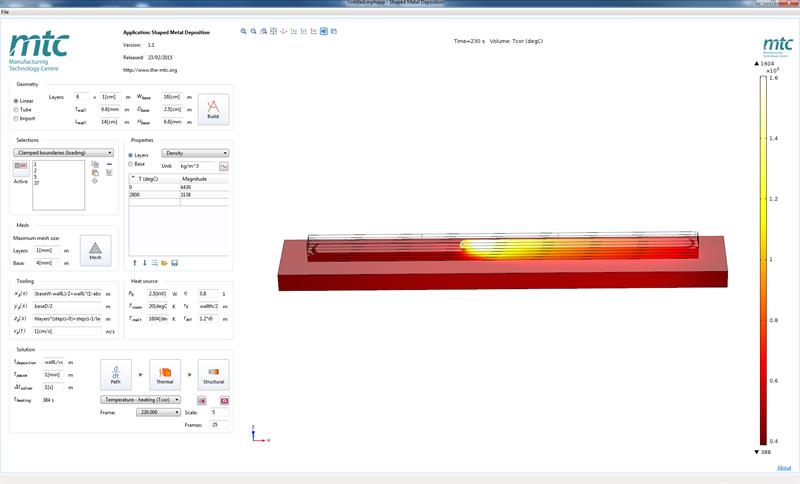

“So we developed this model, using simple rectangular geometry so it is representative of the process and  the distortion,” explained Toralles. “And then the idea is that we can package this up in an app. This means engineers can go away and use more complicated geometries to reduce the number of experimental iterations.”

the distortion,” explained Toralles. “And then the idea is that we can package this up in an app. This means engineers can go away and use more complicated geometries to reduce the number of experimental iterations.”

Figure 1. Top: Simulation of the SMD part. Middle: The part after just one deposited layer, with no noticeable deformation. Bottom: After six deposited layers, deformation is visible to the naked eye.

Figure 1 shows an example of a part manufactured using SMD, where deformation occurs after six layers of deposited molten metal have been laid down. A model of the part, also shown in Figure 1, is used to predict the part’s deflection during manufacturing, allowing the designer to update the design accordingly.

The role of the MTC is to progress its customers’ technologies through the Technology Readiness Levels (TRL), typically taking conceptual projects at TRL of 3 or 4 through to the more commercially viable TRL 7 – 9. In this case developing the technology is one aspect, the other is making it useable.

Simulating the behavior of the SMD models was created using the Comsol Multiphysics software, but to make it useful to engineers it needed to make it accessible. Designers want to know how their designs would work on an SMD machine, they were not necessarily going to be experts in creating complex simulation models. In other words, an easy to use interface was required and for that the simulation team turned to Comsol’s Application Builder.

Intuitive interface

The MTC leveraged the Application Builder in order to more efficiently communicate complex design ideas across multiple simulation and process departments, and to allow app users to easily explore the outcome of proposed designs (see main picture). Were it not for the simulation app, the testing and validation of a design would be significantly more time consuming and costly using physical testing alone, due to the materials used in SMD.

Simulating SMD involves solving a time-dependent coupled thermomechanical analysis that predicts residual thermal stresses and deformation, which arise from SMD thermal cycles.

“We built an app using the Application Builder that allows the user to predict whether the deposition process will produce parts that fall within established tolerances,” said Toralles. “If not, then the app provides a user-friendly and cost-efficient way to simulate multiple variations to the input until the results achieve an acceptable final deformation.”

With this app, users can easily experiment with various geometries, heat sources, deposition paths, and materials without concern for the underlying model complexities. Two predefined parametric geometries are included in the app, and a custom geometry can also be imported.

Currently, the app is being used by members of the team at the MTC who do not have the simulation experience to independently explore different parts and projects for their customers. “Were it not for the app, our simulation experts would have to test out each project we wanted to explore, something that would have decreased the availability of skilled resources,” claimed Toralles. “Using the Application Builder, we can now provide user-friendly app interfaces to other MTC teams.

“It democratises simulation because it makes it available to more people that are not experts in simulation. They don’t know about or maybe not been trained to use simulation tools. They just care about the inputs in essence.”

The MTC will also offer an app program for their customers, concludes Toralles: “The use of simulation apps will help us to deploy technologies at higher TRLs for their practical use in an industrial environment. The Application Builder provides us with a powerful development platform through which we can package complex multiphysics models and make them accessible to the wider public.”