Super wipes are cool for cleaning and blowing

The normal method for blowing off, drying, cleaning and cooling the surfaces of pipes, hose, tubes and extruded shapes is to use a ring of air nozzles

Problem: . But this often leads to poor results with inconsistent air velocity levels, plus high noise levels and high air consumption.

Solution: Goodhand UK's 'Super Air Wipe' device (developed by Exair) delivers a circular air stream that adheres to the surface of the product passing through it. And the split design makes it easy to clamp around the surface of the product. The new device ejects a small amount of compressed air through a thin slotted nozzle that pulls in high volumes of surrounding room air. The airflow it produces uniformly ejects from the inner diameter. Air velocity can be varied from a 'blast' to a 'breeze' with instant on/off control. Coupling brackets hold each half of the device together, enabling it to latch or be removed quickly.

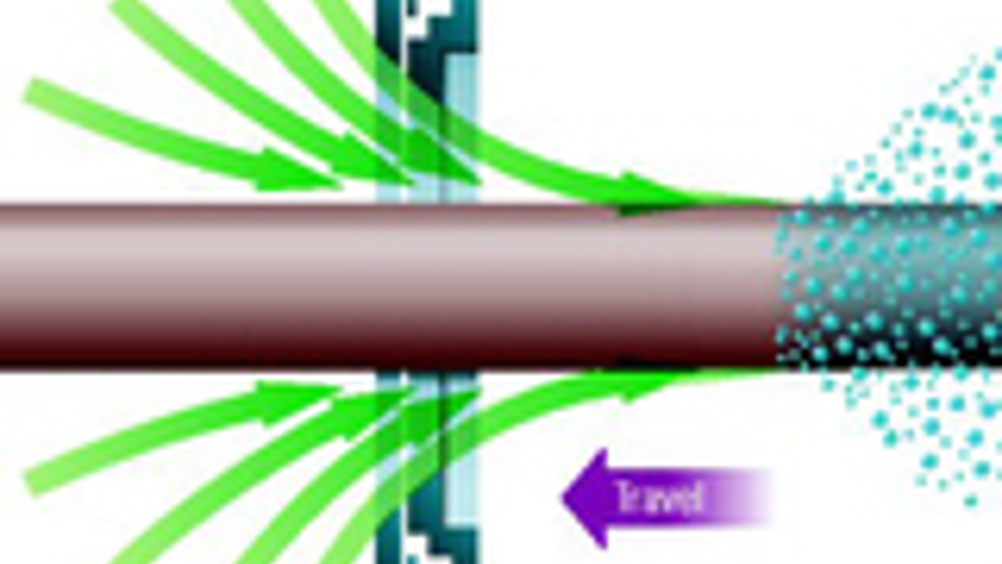

Compressed air flows through an inlet (see diagram) into an annular chamber. It is then throttled through a small ring nozzle at high velocity. This primary airstream adheres to the coanda profile, which directs it down the angled surface of the device. A low pressure area is created at the centre inducing a high volume flow of surrounding air into the primary airstream. As the airflow leaves the unit, it creates a conical 360° ring of air that attaches itself to the surface of the material running through it, uniformly wiping the entire surface with the high velocity airflow.

Goodhand advised Eureka that additional shims can be installed if more blowoff force is required. Tapped holes are provided on the bottom for permanent mounting. The unit is constructed from aluminium and comes in 25mm to 275mm throat diameters.

Applications: Super Air Wipes are suitable for a wide variety of applications including the drying of inks; paint and screen printing; cooling hot extruded shapes; and blowoff of water, dust, plating, coatings and contaminants. DP