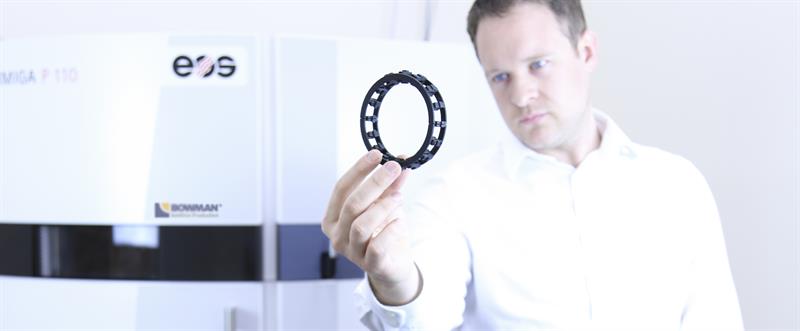

Jacob Turner, head of additive production at Bowman, explains the significance. He says: “Historically, additive manufacturing has been the domain of those wanting to prototype quickly. Very few innovators take the next step, which is true component production.”

Bowman Additive Production is a response to growing demand for a time and cost efficient manufacturing process, that is both flexible and also capable enough to produce increasingly complex parts.

“We can add complexity to a bearing design without adding cost,” says Turner. “For example, we can add bronze inserts into the design, which means we can add a lot of features which aren’t possible with any other area of manufacture.

“We do this on our split bearings, so we’re able to interlock the cage in a way that you wouldn’t be able to do otherwise.”

By adding these features, higher strength and wear resistance in Bowman’s split bearings can be achieved, which are ready for applications in harsh working environments such as driveshafts in the marine, mining and steel industries.

Additive manufacturing technologies are well known for their ability to produce complex geometric shapes without incurring cost. Engineers have traditionally struggled to incorporate more complexity in to bearings due to reliability issues and the need to keep costs down. Like many others, Bowman has found that if a new design concept is not cost effective to produce, traditionally it will not move past the concept stage.

“That’s a real benefit with additive,” says Turner. “A more complex design allows us to add more rolling elements to the bearing, which in turn increases its working life. So, we can get a much higher performance just by changing the cage.”

Bowman is now producing these more complex designs using 3D printing, which it reports enables its split bearings to increase load bearing capacity by 30 to 40%, and offers an increased working life around 300%.

Tooling benefit

Like many other companies experimenting with 3D printers, Bowman is finding that its additive manufacturing processes help reduce spiralling tooling costs, when alterations are needed.

Paul Mitchell, managing director of Bowman International explains, saying: “We can easily produce different iterations of a cage at no cost using additive manufacture. Whereas with tooling you’ve got to design and make a tool, which is going to be costly and time consuming.”

It’s meant traditionally, for relatively low volume production of special cages for example, there is a cost barrier stopping innovation.

“This is a cost effective way of making a cage that is not able to be produced by any other methods,” adds Mitchell. “We’ve designed and made it using 3D printing and that gives us the 30-40% extra load bearing capacity.”

The ability to tailor a cage has meant there is more contact with the load, making a big difference in overall life, reportedly up by some 300% on some AM bearings.

“The piece part saving for us is not huge, but there’s a potentially huge saving in tooling,” says Mitchell. “If you’re tooling a bearing cage, that can be as high as £40,000 to £60,000 for the set. That’s not needed anymore.”

By utilising additive techniques, Bowman is able to design and deliver modified, low volume or complex component parts to the market in quantities between 20 and 20,000 units. It’s no longer a one size fits all, but a tailored offering depending on what’s needed.

“The main thing for us is that it’s a production process and that’s how we’re coming at it,” says Mitchell. “Yes, we produce prototypes, but we’re interested in production-ready parts because that’s what our business is. This blurs the lines between prototype and production parts because the prototype, as you might call it, is actually a production part.”

With such flexibility on unit quantity, customers can also benefit from the production of niche component parts that would otherwise prove too costly.

Evolution cages are manufactured without tooling and therefore offer a highly competitive cage option for low to medium run bespoke bearings. Manufactured from engineering grade ‘printable’ nylon (PA1102) with bronze-alloy inserts made from ‘ToughMet’, the cage delivers the wear properties of ultra-high load bronze with the design complexity synonymous with 3D printing. The cage greatly reduces wear on rolling elements when compared with conventional steel cages.

“The work Bowman has conducted in the 3D printing field using composite construction techniques combined with ToughMet3 has resulted in 3D printed plastic parts, which are able to outperform any metallic based components currently available,” says Turner.

Bowman has also selected to work with a Nylon 11 polyamide made from entirely renewable sources that features elasticity and high impact resistance.

Whilst most manufacturers remain focussed on using aesthetically tuned materials for visual prototyping, Bowman AP will join a select group of companies in the UK able to offer this engineering material for the production of functional parts.

Bowman AP will also act as a sub-contracting service for manufacturers that want to produce custom parts and tooling moulds.

3D printed bearings

Additive manufacturing is also high on fellow bearing manufacturer, Schaeffler’s, development roadmap. It has recently signed a cooperation agreement with machine tool company DMG MORI, to develop additive manufacturing processes for rolling bearing components.

The goal is to develop laser metal deposition welding, an additive manufacturing technology that can be used for the flexible prototype of rolling bearing components and small batch sizes.

The focus is on process issues as well as material application. In laser metal deposition welding a material, in this case metal powder, is simultaneously melted and applied to the surface by a high-performance laser. This additive manufacturing process can be combined with conventional five-axis machining in the hybrid facilities developed by DMG MORI. The result is a 3D printer that can post-process a part all in a single build envelope – allowing the collaboration of both subtractive and additive operations. Operators of machine tools in particular will benefit from the partnership.

The future

The two companies are focussing on different bearings so far, but Bowman sees the potential for expanding as time goes on.

“Within the split bearing market [this process] should become fairly standard,” says Turner. “We’ve got parts that are already in the late stage of design and some are going through the process of being patented that will be coming shortly.

“It’s never going to replace the billions and billions of cheap ball bearings that you can buy, but it is a very large market.”

The biggest advantage for bearing manufacturers is in the flexibility additive manufacturing affords. Rather than starting from scratch and having to build expensive tooling for each product, 3D printing is allowing a multitude of specifications as far as the shape and design is concerned, to be produced in almost any quantity without a huge cost penalty.

Products can be designed that would never have been viable to produce previously because the market is too small to produce them economically. However, there is huge potential for producing small batches of parts, which Schaeffler and Bowman are only just beginning to look in to.

Beamline business Boost

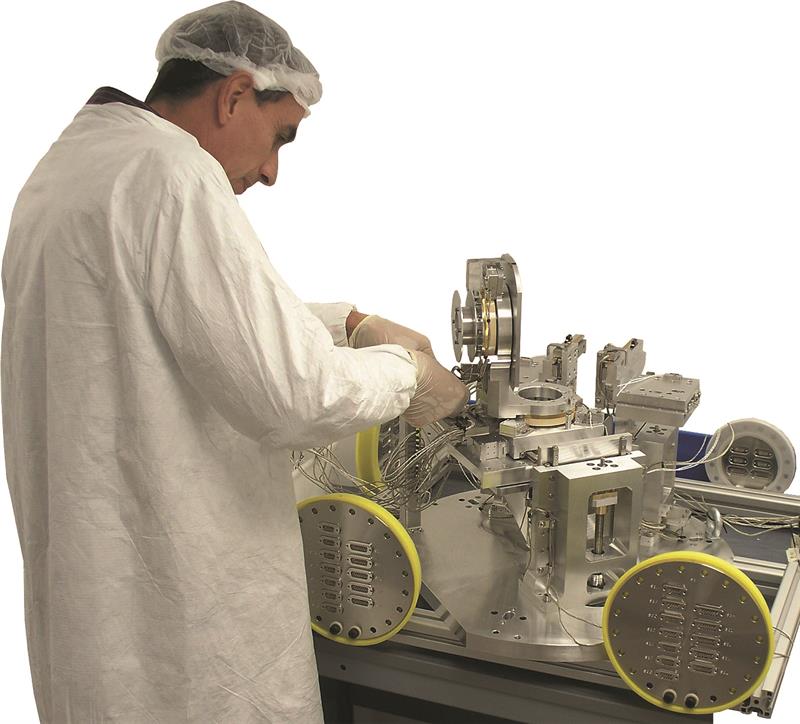

Applications normally involve custom engineered high precision positioning tables and motion controls for mounting and manipulating samples under study as well as slits for beam collimation and micro-positioners for aligning focussing mirrors. As the beamlines operate in vacuum conditions and some positioning systems are held in vacuum chambers, many applications involve ultra-high vacuum (UHV) compatibility. Further requirements characteristic of such applications are the exclusive use of non-ferromagnetic materials that do not influence subtle instrument measurements. Rigorous temperature and pressure cycles can also be involved with temperature regulation also critical to maintain the sub-micron, and in some cases, nanometre levels of precision demanded. With its own in-house motion systems design and mechatronic system integration capability, Heason Technology brings these specialised components together for turn-key multi-axis positioner projects, showing the UK’s growing ability to deliver world beating scientific motion control systems that are difficult to design and produce elsewhere. Components specific to these demanding applications include piezo-ceramic direct drive linear and rotary motor systems, vacuum compatible optical encoders, vacuum compatible stepper motors, ceramic bearings and all-stainless cross roller bearings with low magnetic permeability. A 2m travel single axis linear stage with a ceramic motor drive that positions to 50nm resolution through a linear encoder with speeds to 80mm/s is used in a cryogenically cooled vacuum chamber. A 5-axis UHV compatible motion system has sub-micron resolution for precise X, Y linear and pitch, yaw and roll positioning of a 120kg load – with a sophisticated motion control system that includes kinematic transformation for its rotary axes. A 14-axis linear and rotary UHV compatible and low magnetic positioning system positions samples and optics in a 550mm diameter vacuum chamber with optical encoder closed loop feedback with resolution to below 50nm. Heason Technology is also at the forefront for the design of specialist slit packages that are used to control the physical width of the beam and its angular spread enabling research scientists to ‘tune’ the beam to achieve the optimal frequency required for the materials being examined on the synchrotron instrument. These collimators are typically 4-axis ceramic motor driven linear blades with sub-micron resolution supported in ceramic bearings housed in aluminium frames. |

West Sussex motion specialists Heason Technology has won a number of high profile motion control projects from leading synchrotrons in Europe and the US. Successful systems installed at beamline sites include Diamond Light Source, Rutherford Appleton Laboratory and Brookhaven National Laboratory in the US.

West Sussex motion specialists Heason Technology has won a number of high profile motion control projects from leading synchrotrons in Europe and the US. Successful systems installed at beamline sites include Diamond Light Source, Rutherford Appleton Laboratory and Brookhaven National Laboratory in the US.