From a technological point of view, however, the final SolidWorks World had a number of announcements to offer. The most significant of these was the announcement on the first morning of the opening day of the introduction of 3DExperience.Works, which is a new portfolio of industry-aware applications on the 3DExperience platform that is tailored to the needs of SolidWorks customers and small and mid-sized companies everywhere. 3DExperience.Works combines social collaboration with design, simulation and manufacturing ERP capabilities in a single digital environment to help growing businesses become more inventive, efficient and responsive

3DExperience.Works is designed to extend the ease of use and reach of SolidWorks. 3DExperience.Worksis a new range of offerings on the 3DExperience platform that comprises simplified DS applications. Dassault Systèmes created 3DExperience.Works following its acquisition of IQMS, whose manufacturing ERP software portfolio for midmarket manufacturers has since been rebranded as DelmiaWorks. 3DExperience.Works is targeted at the SolidWorks community as a way to transition users to an introductory level of the 3DExperience platform.

“Small and mid-sized firms worldwide need digital solutions to grow but have long been challenged to find ones that are right for their size. By introducing 3DExperience.Works, we bring the platform effect to them,” said Bernard Charlès, vice chairman and CEO, Dassault Systèmes. “We see the benefit the 3DExperience platform has quickly brought to designers using SolidWorks to expand their business. The 3DExperience.Worksfamily now includes DelmiaWorks to serve mainstream manufacturers by providing a full digital thread for business operations. The 3DExperience platform is poised to become the benchmark for business operations in this category of firms through well integrated offerings spanning manufacturing and management that are simple, affordable and easy to implement.”

3DExperience.Works will allow small and mid-sized companies to perform their work using a single cohesive digital environment instead of using a complex series of point solutions that require jumping between applications and interfaces. 3DExperience.Works connects data and streamlines product development processes by providing dashboard templates, managed services, access to industry-focused communities and user groups, and applications specific to a variety of job roles.

With other complementary DS products (brands), 3DExperience.Works is intended to cover the product development lifecycle and its phases with specific functions provided by the brands:

Dassault says generations coming up have been living in a connected world and they’re ready for PLM, but not PLM as it has been offered, a heavy and complex tool requiring dedicated professionals to build and maintain. Dassault pledges to ready young workers who are arriving with the expectation of being always connected to intelligent machines. PLM for everybody.

During his keynote, SolidWorks CEO Gian Paolo Bassi said: “Connected 3DExperience.Works will help us lead the way for an Industrial Renaissance.” He also claimed the new tools will help customers integrate processes for Plan, Design, Simulate and Manufacture and benefit from Dassault’s 3DExperience platform.

Manish Kumar, SolidWorks R&D president, the strategy for 3DExperience expanded on this, making it clear that these four areas would be covered respectively by: ENOVIA (Plan); SolidWorks (Design); Simulia (Simulate); and Delmia (Manufacture).

With regard to planning, he said: “Our future generation is growing up in an entirely different world than the one we grew up in. This generation is connected to a global world of intelligent machines and computing power. As they become our next workforce, we need to be ready for their needs.”

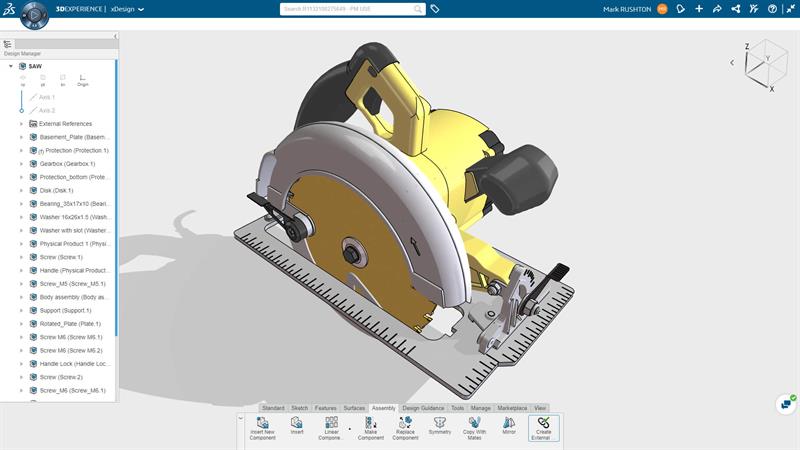

As far as design is concerned, the R&D team has been busy creating and delivering hundreds of new enhancements in SolidWorks 2019 and now working on SolidWorks 2020. Their work is based largely on customer feedback. Talking about what they are doing to be ready for 2020, which the company sees as a pivotal year for SolidWorks. Dassault has transformed its R&D to be a core resource for the entire company. Tools like xDesign and xShape are cloud-based, easy to-use design tools designed to complement the SolidWorks design environment.

Simulation has finally become part of many designers’ workflow, but as customers adapt to simulation, they’re finding situations where they need simulation to adapt to their problems. Dassault is trying to develop tools that address complex simulation challenges within a familiar environment for SolidWorks users. Sometimes a more powerful tool might be the easier solution if it’s faster and more powerful. Dassault is working on tools from Simulia that are streamlined for SolidWorks.

The manufacture side of 3DExperience.Works includes the Delmia products and the 3DExperience Platform Marketplace where customers can source parts and find suppliers.

Other highlights to look out for in 2019 include: flexible parts that can be made physically flexible in an assembly, and they update automatically as their references change;Markups available in parts, assemblies and drawings using touch-enabled devices as well as eDrawing;a 3DExperience Platform Connector for SolidWorks, which provides interoperability between SolidWorks and 3DExperience Platform apps; Routing Mass Properties for wires, cables and coverings include mass properties that update assembly mass properties; and Torsion Continuity Sketch Relation a continuity relationship for splines used to create high-quality smooth sketches that support creating surfaces.