The aerospace industry has been a big adopter of additive manufacturing, and is on a continual mission to make components lighter without compromising on strength. Even aircraft engine blades are constructed via additive manufacturing. Rolls-Royce’s engine blades are produced by a technique called laser metal deposition, where metal powder is blown coaxially into a laser beam, which melts the particles on a base metal to form a metallurgical bond when cooled.

The blades are made from titanium and nickel super alloys and are arranged in groups called ‘blisks’ (bladed discs) rather than individually as they weigh less when arranged in this fashion. When a blade is damaged, due to the intense heat and pressures under which they operate, the blisk is removed, the damaged part is milled off and replaced via laser metal deposition.

In an attempt to remove as many defects as possible, Rolls-Royce is working with AMAZE, a collaboration of 26 European institutions from academia, research and industry, at the Diamond Light Source synchrotron in Harwell, Oxfordshire. The science behind the synchrotron is incredibly complex, but the basic principle is outlined by Professor Andrew Harrison, CEO, Diamond Light Source: “What we have is a storage ring which circulates electrons close to the speed of light. As it goes round the ring the current of electrons gives off a brilliant flash of light in the x-ray part of the spectrum – we use that light to feed instruments that we think of as very high powered microscopes.”

This allows the scientists to study the structure of materials at the atomic scale. In a lab, x-ray technology allows for around 100 frames to be

captured per second, the synchrotron beam allows for 10,000 fps.In this case, it means that the teams from AMAZE and Rolls-Royce can study how uniformly their materials form as they are being deposited by the laser layer by layer.

Alex Leung, aerospace materials engineer from the University of Manchester, one of the research partners on the AMAZE project, says: “You can see molten pools forming and also defects developing during the melt track evolution. We also see lots of powders that are blowing off – ejecting away from – the powder bed. Some of them may be melt droplets which could add to surface roughness on the additive manufacturing component.”

This roughness caused by these rogue powder particles could affect the performance of a turbine blade. The cumulative effect of this throughout a whole engine turbine, or even every turbine produced by this method, adds up to a waste of material as well as reduced efficiency which affects fuel consumption and thus running costs.

“You want to make something that is perfectly smooth. You want to get all of the powder into there,” Leung continues. “Looking at just a single layer may not be representative. What we have done is add more powders onto the layer above and then repeat the process which is exactly what happens in the real-life process.”

The scientists are trying to correlate the masses of data produced by their experiments – the group creates around 500 terabytes per year – to find areas in the process that can be easily measured in commercial industrial additive manufacturing where fluctuations on the surface can be easily observed.

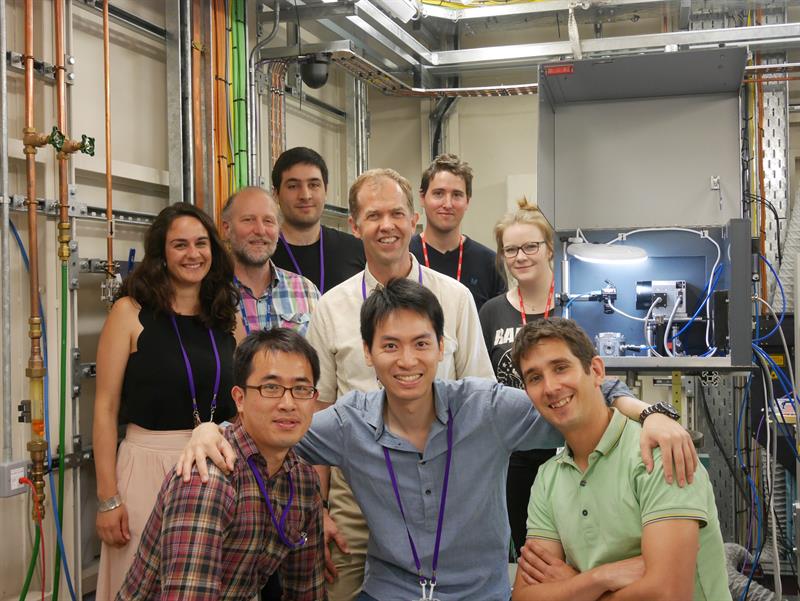

Prof Peter Lee (middle of group) and his team (including Alex Leung - bottom row, centre) in the beamline at Diamond Light Source

Peter Lee, Professor of Materials Imaging at the University of Manchester and leader of the AMAZE project, explains: “The controllable point [of laser metal deposition is] just above the surface, where the laser hits the powder. No one actually knows what happens from then on. We are not really sure whether the laser is melting it on the surface or melting the powder in the air. You get powder blowing off the side, you get oscillations in the surface and we are not sure why. We are hoping to make it so for the first time you can see what is happening inside that nozzle.

“Manufacturers know they will see various fluctuations, but they don’t know what causes them. The goal of this is to say what causes them and then use other lower cost, faster techniques to make better components.”

The final aim would be closed loop control using machine learning to create the most uniform deposition possible which Prof Lee says will be part of the project in the longer term.

After a year and a half working on this project, the team are close to publishing their results. After publication, Rolls-Royce will be able to implement what it has learned into its additive manufacturing processes. As it has the potential to increase engine performance, reduce CO2 emissions and noise on take-off and landing, and most importantly save money by reducing the number of damaged components, as well as making additive manufacturing faster and more efficient.

As for Prof Lee and his team, they are continuing to research areas as disparate as shock mechanics in 3D printed medical implants, whether the smoothness of ice cream makes it taste better and even replicating a volcano to study magma flow as well as pushing the synchrotron’s resolution from 10,000fps to 100,000fps.

Fast facts

|