Delo Industrial Adhesives has developed a portfolio of dual-curing adhesives based on dissimilar chemistries, which, it claims, offers significant advantages over more ‘traditional’ adhesives, without sacrificing reliability, bond strength or ease of use. Uses include industrial displays, automotive camera modules, electric motors and even simple applications, such as thread-locking.

When bonding components together, it is essential that the whole volume of the adhesive is fully cured, as uncured adhesive in the finished assembly may cause corrosion or, in the case of optical products, interfere with the light path. For light-curing adhesives (ultra violet and visible light), achieving full cure can be a problem, due to shadow areas that the light can’t reach. Heat-cured adhesives do not suffer from this problem, but some components can be sensitive to temperatures even as low as 90-100oC.

Two-part cold-cured adhesives, such as epoxies and polyurethanes, can overcome this issue, but the user then must suffer from the long curing times these adhesives require, thereby increasing cycle times and reducing throughput.

Diverse curing mechanisms

Dual-curing adhesives overcome these issues in different ways, depending on the chemistry of the adhesive. Currently, hybrid light and heat curing adhesives appear to be the preferred solution, but other chemistries, such as light and humidity and light and anaerobic adhesives, are gaining in popularity.

Light and heat cured adhesives

These are based on two diverse chemistries, epoxy and acrylate. Epoxies tend to be hard once cured, offering increased resistance to chemical and temperature stresses, on account of the tight cross-linking of the polymer that occurs during cure. Acrylates are usually softer adhesives, enabling quicker curing and greater flexibility of the cured adhesive.

Using a combination of heat and light to cure these adhesives offers the user a very fast fixation by snap-curing the photoinitiator in the adhesive. Subsequent heat curing ensures there is no uncured adhesive in any shadow zones that might exist in the assembly. This fast fixation also allows increased accuracy for the user – this is especially useful for companies that have invested heavily in high-accuracy placement machines, only to see that investment wasted, due to movement of the parts being bonded during the heat-cure stage.

According to Eamonn Redmond of Inseto, Delo’s UK agent since 1998, customers’ feedback has been incredibly positive when it comes to accuracy of bonded parts, with less than 1µm of movement during subsequent heat-curing, as a direct result of light-fixing the adhesive. “This is just not possible with adhesives that are only cured by heat,” he said.

This heat-cured stage generally involves heating the parts up to around 100oC after the light cure process. However, for temperature-sensitive materials, such as some plastics, modified epoxy adhesives are available that will cure at 60oC, combining defined processes and short cycle times, despite the low curing temperature of the adhesive. These are especially useful in applications such as automotive camera modules or where the end product is subjected to chemical influences that would otherwise harm an acrylate adhesive. These dual-curing epoxies also exhibit very low outgassing (some are NASA-qualified) and low yellowing, making them ideal for applications with demanding optical requirements, such as LED assembly.

Dual-curing acrylates offer similar advantages to dual-curing epoxies, namely very fast fixing and full cure after subsequent heat curing, but these adhesives also exhibit excellent impact resistance and tension-equalising properties, because of their flexible nature. These are ideally suitable for applications such as the assembly of rotary encoders, where optional fluorescing and colouring can be added to aid visual inspection.

Light and heat cured adhesives also offer increased flexibility in the manufacturing process. While heat-curing is mandatory for a small number of these adhesives, the majority offer independent curing mechanisms, allowing curing either by light, or by heat, or by a combination of the two.

Light and humidity cured adhesives

Light and humidity cured adhesives also enable a fast fixation by light, but the secondary curing mechanism in this instance is humidity, so there is no requirement for additional curing equipment. The majority of the assembly should be capable of being cured by light, to achieve optimum bond strength, but for applications such as mobile phone displays, where only the black border prevents light getting to the adhesive, then humidity curing at a rate of 2mm/day is the ideal secondary curing mechanism, enabling immediate handling after the initial light-cure process.

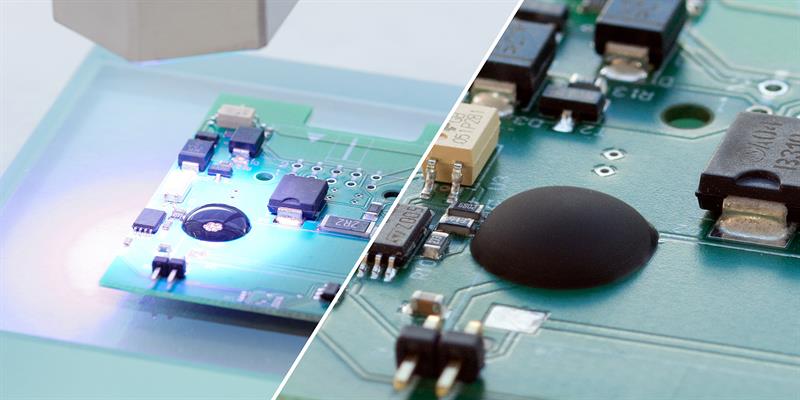

Light fixable anhydrides used on a PCB

These are also single-part adhesives, and are free of isocyanates (no health & safety issues) and silicones (no impediment to subsequent adhesive bonding), unlike some acrylates. They are highly flexible, optically clear adhesives, offering significant climatic resistance, while also providing powerful bond strength on surfaces such as glass, PMMA, metal pins and most plastics.

Light and anaerobic cured adhesives

Anaerobic adhesives cure in the presence of metal and the absence of oxygen, but, in a lot of cases, the adhesive at the edge of the joint is exposed to air, which results in a small amount of uncured adhesive, possibly at either end of the bond. By using the photoinitiator in the adhesive to snap cure the edges of the joint, a 100% cure of the adhesive then becomes possible. For example, Hall Effect sensors are used in automotive applications when position or speed needs to be monitored. These sensors are sometimes located directly on the wheel rim or even on the wheel hub. From there, they provide accurate information on how frequently the wheel is rotating. Using light and anaerobic dual-curing adhesives for these applications is especially appropriate, because they assure a rapid fixation and a secure final curing, even in shadow zones. These adhesives are also highly resistant to media such as oil, gas and braking fluid, and they also meet JEDEC requirements for salt spray, reflow, vibration and drop tests.

These adhesives also offer an extended temperature resistance of -60oC to +180oC, making them suitable for applications such as e-motors where a lot of heat is generated. As they also exhibit excellent adhesion to most metals and plastics, with very high impact resistance, they are used for the assembly of slot magnets and temperature sensors.

Dual-curing adhesives provide increased flexibility in the manufacturing process, giving end users more freedom when designing the manufacturing flow. They eliminate the unwanted possibility of uncured adhesive in the end product and offer maximum placement accuracy when building complex assemblies on expensive equipment.