In order to meet high consumer demand for the latest smartphones or laptops, production in the electronics industry must move at breathtaking speeds while still being precise and accurate enough to achieve repeatability and consistently high quality. Understandably then, the electronics industry is very well suited to automation.

The fundamental element of any automated production cell is how to guide and transfer a component around the system between processes so that it can precisely interact with integral robotic or actuator systems.

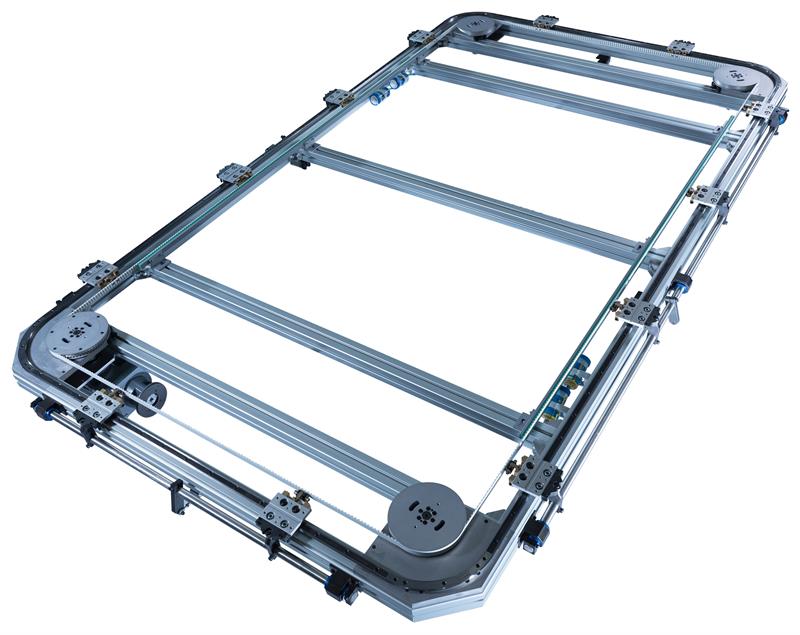

Belt-driven track systems do just that. They are supplied as ready-assembled units, providing a facility to drive carriages around a track circuit under either continuous or intermittent motion. Track systems are designed to form the foundation of an automated production cell, and electronics is one of the key industries using it.

Cutting-edge production

Undoubtedly, the most prominent producer of high-tech consumer electronic goods and components today is China. British-based Hepco is a regular supplier of driven track systems (DTS) into China and many other Asian markets, where they are used to form the foundation of automated production cells.

Undoubtedly, the most prominent producer of high-tech consumer electronic goods and components today is China. British-based Hepco is a regular supplier of driven track systems (DTS) into China and many other Asian markets, where they are used to form the foundation of automated production cells.

Hepco’s products are exported to China from the UK and used in the manufacture of leading consumer electronic products. These are then sold across the world, and then back in to the UK.

iPhone 8 production

Many belt-driven track systems in China are utilised for the automation of smartphone production; battery inspection operations and lithium-ion battery production. Indeed, Hepco’s DTS products are core components in the automated production of Apple’s iPhone 8.

In this production line (which was designed, built and commissioned on behalf of Apple by Foxconn, the world’s largest producer of electronic products) there are a number of key processes being performed on the DTS. These include the assembly of components within the phone, testing the phone and inspection of the screens.

Repeatable accuracy

This application requires a consistent level of precision to ensure belt-driven track system carriages, which carry the products, are aligned correctly to production equipment and processes. The DTS incorporates a carriage locking system capable of aligning carriages to a repeatable position anywhere along a straight section of the circuit to ±0.05mm.

This feature is particularly beneficial for applications using intermittent motion and ensures precise location of components while operations such as drilling, soldering or assembly take place. This high level of accuracy and repeatability meets the stringent quality standards of world leading electronics companies such as LG, Samsung, Apple and Huawei.

Small footprint

In an environment where space is at a premium, a compact, space-saving production cell is high on the agenda. The benefits of an oval or rectangular track system over a straight linear system are clear to see, with oval or rectangular systems effectively able to reduce the footprint by up to 50% by turning back around on themselves.

In an environment where space is at a premium, a compact, space-saving production cell is high on the agenda. The benefits of an oval or rectangular track system over a straight linear system are clear to see, with oval or rectangular systems effectively able to reduce the footprint by up to 50% by turning back around on themselves.

The curved ring sections are effectively used as a return, guiding the carriages back to the straight section where processing work is done. Equipment can be located inside or outside of the track shape, again, saving valuable production space and creating a compact, space saving production cell.

Hepco’s DTS is available as either an oval or rectangular circuit to suit specific application requirements and is available in any length. Customers can choose the exact number of carriages they require; limited only by the system size. Saving time, DTS is a complete unit ready to be incorporated into a continuous positioning or dedicated assembly machine.

The provision of all transmission and mounting components as a complete integrated package means huge savings are made in both design and build time.

V Guide technology

A key requirement of all automated production cells is the need for low maintenance. Systems that can deliver continuous and smooth operation, without the need to be regularly stopped for routine maintenance such as re-lubrication, are highly valued by designers and production engineers the world over.

The DTS is based on Hepco’s precision V guide technology, rigidly guiding the carriages around the track, ensuring accurate alignment and resistance to deflection. In an automated assembly cell, the ability of the carriages to accept the necessary assembly forces while maintaining good levels of rigidity is a key requirement.

Bleed lubrication

Hepco’s bleed lubrication system automatically delivers a steady and consistent supply of lubrication directly to the running faces of the V track. Using a lubrication canister that can be set to dispense over a period of up to 12 months, bleed lubrication effectively eliminates the need to stop production in order to re-lubricate the track.

When the remotely-located lubrication canister comes to the end of its life, it can simply be replaced while the track system is still moving.

With end users including electronics giants LG, Samsung, Apple and Huawei, automated production cells meet the demanding needs of some of the biggest global technology leaders, and are key elements in producing the technology we rely on.