Known for its luxury sports cars, which have become an automotive industry standard for speed and performance, Ferrari is also known for its success in Gran Turismo (GT) racing. Each year, the Ferrari Competizioni GT racing organisation competes in about 25 international events, battling teams from around the world. Its engineers work constantly to optimise aerodynamics and other aspects of vehicle designs, with the goal of crossing the finish line first and reinforcing Ferrari’s brand leadership.

Every two or three years, the Ferrari Competizioni GT engineering team pushes itself to engineer an upgraded GT race car within a 12-month window. These changes must not only improve performance but must reflect new industry standards introduced by the Fédération Internationale de l’Automobile (FIA). To meet this aggressive schedule and succeed in this intensely competitive environment, Ferrari identifies and applies the most innovative engineering technologies available. The team is constantly adopting the most advanced simulation capabilities, as well as best-in-class engineering simulation practices.

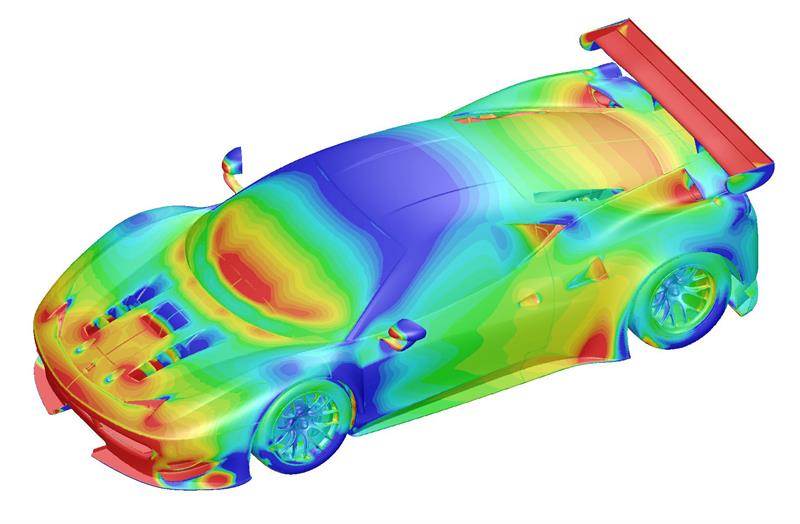

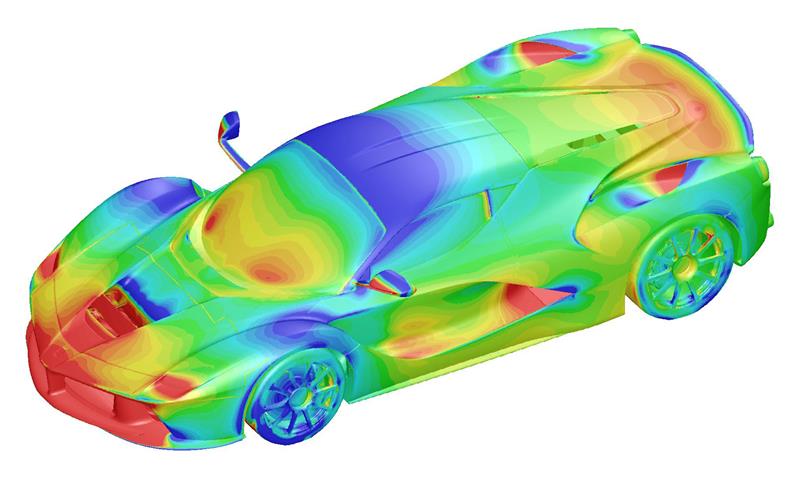

“For years, Ferrari Competizioni GT has leveraged the power and scope of ANSYS Fluent computational fluid dynamics (CFD) software to optimise the aerodynamics of its race cars,” explains Ferdinando Cannizzo, Ferrari Competizioni GT’s head of GT racing car development.

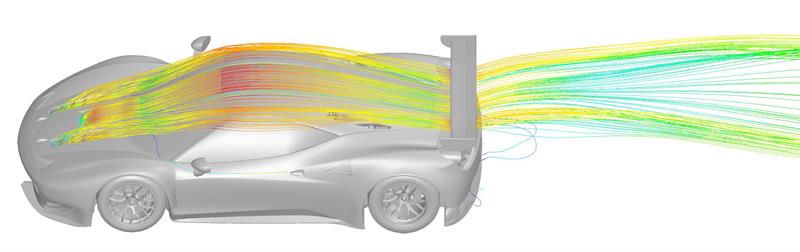

“Supplementing physical wind-tunnel testing — which is time- and cost-intensive — with CFD simulations in a virtual world has yielded significant benefits for Ferrari.

“Engineers can generate a fully realised, virtual 3D vehicle designs much faster than building a physical prototype — then test a large population of geometrical variations to assess their effects on the model’s aerodynamic performance.”

This allows Ferrari’s product development team to build expensive, scaled-down prototypes of only the most promising designs to validate with physical wind-tunnel testing. This process has proven highly successful, cutting time and costs from the overall design cycle for a new race car.

Breaking away from the pack

In the past, Ferrari engineers used CFD software to generate a finely detailed mesh around the race car, which enabled flow simulations at a very high degree of accuracy. However, creating this fine mesh and running CFD simulations on it required a high level of expertise and meant hours of hands-on time spent optimising mesh quality — resulting in a large computational size and a correspondingly long run time for each CFD study.

According to Cannizzo, Ferrari responded to this challenge by adopting ground-breaking new simulation capability in the form of mosaic meshing technology. He says: “ANSYS Fluent Mosaic-enabled poly-hexcore meshing has enabled the Ferrari Competizioni GT development team to achieve both a meaningful mesh resolution level and rapid results, achieving an even higher level of simulation accuracy with fewer cells, leading to less manual work and a much faster solution time.”

The Fluent solver handles hexcore cells efficiently, enabling the Ferrari team to achieve productivity gains. This meshing capability also supports fully automated meshing, with little to no user intervention. Once a new design option has been defined, its surface mesh is automatically partitioned and sent to different cores of a distributed, parallel computing architecture. By batch executing the standard, repetitive tasks involved in meshing via Mosaic-enabled technology — combined with robust Fluent Meshing native scripting — even less-experienced engineers can realise a four-times speedup in meshing speed and efficiency. This means that Ferrari designers can look at a larger number of geometry options very quickly, thanks to the built-in automation of Fluent’s task-based meshing workflows.

“In the past, users had to create custom scripts to enable automated meshing — but now an entirely new vehicle geometry can be introduced and automatically meshed in just a few hours,” says Cannizzo. “Innovations such as Mosaic meshing in ANSYS Fluent have enabled tremendous workflow and productivity benefits for Ferrari Competizioni GT.”

This automated workflow boosts productivity by reducing the user learning curve, minimising the chance of human error, and freeing engineers to focus on higher-value work. This helps the Ferrari development team make significant changes every three years and prepare a new car for the racing season in less than a year, with a limited amount of resources.

“Thanks to Mosaic-enabled poly-hexcore meshing, Ferrari engineers have been able to decrease the number of meshing cells by 15%,” Cannizzo says. “This reduction, when combined with the new hex-dominant mesh, delivers solution times that are twice as fast. For an organisation focused on speed, that is an enormous improvement.”

By relying on Mosaic technology and the Fluent end-to-end workflow, Ferrari engineers can run three times as many CFD simulations in the same amount of time — and can develop cars faster than ever before.

Ferrari and simulation: A winning combination

GT competitive racing has always been part of Ferrari’s DNA. Ferrari Competizioni GT is racing two cars in the 2019 season: the 488 GTE and the 488 GT3. These two turbo-engine cars will compete in the most demanding endurance races and the most important national and international GT series. The 488 GTE has already won two Manufacturers’ titles in the FIA World Endurance Championship, while the 488 GT3 has won more than 230 races, two IMSA GTD class titles and one Asian Le Mans Series Championship.

“Ferrari’s adoption of the most advanced simulation tools has been an important element in this successful track record,” explains Cannizzo. “In the modern competition environment, simulation is essential to provide a reliable answer to the tough challenges associated with GT racing.

“Without simulation, no team stands a real chance of delivering results in a cost- and time-effective manner. Ferrari Competizioni GT’s use of advanced simulation capabilities, including the Mosaic meshing and the watertight workflow, has given the team a dramatic performance advantage on the track.”

In June 2019, the Ferrari team won the 24 hours of Le Mans for the 36th time driving the 488 GTE. Cannizzo adds: “Ferrari will always invest heavily in research and development, including engineering simulation, to make sure the company retains its edge as technologies change.”