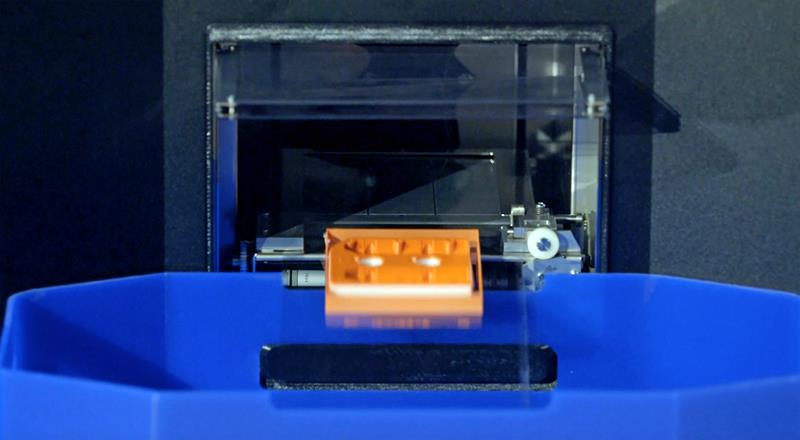

The platform is composed of a modular unit with multiple print cells working simultaneously and set out like racks in a data centre. It is driven by central, cloud-based architecture that is designed to produce parts in a continuous stream with only minor operator intervention, automatically ejecting completed parts and commencing the build of new ones.

Roger Kelesoglu, director of sales enablement at Stratasys, explains: “Talking to our customers over the years, we found that in order to produce a scalable additive manufacturing solution, we need to have an automatic work order print set up and that the workflow should be as automatic as possible. We need to have modular and automated additive manufacturing cells, and that’s what this demonstrator has.”

Each cell can produce a different part to help enable mass customisation projects. Additional cells can be added at any time, without limit, to increase production capacity as demand requires. Automatic queue management, load balancing and architecture redundancy further lead to accelerated throughput as jobs are automatically routed to available print cells. Plus, if a print cell fails, the job will be automatically rerouted to the next available cell.

Tim Bohling, chief marketing officer at Stratasys, says: “We believe – and our beta customers and partners affirm – that this really fits a market space for production without tooling, whether it’s one part or 1000 unique custom parts.”

Target applications include in education RP labs and environments that can benefit from zero tooling production, a zero-inventory supply chain and higher throughput. The beta customers involved in testing the printing platform include Savannah College of Art and Design (SCAD), In'Tech Industries and FATHOM.

SCAD is an art and design university, that has installed a Stratasys Continuous Build 3D Demonstrator in its Design Lab to ensure that all students have 24/7 access to its state of the art 3D printing services. It is said to expand student learning opportunities in 3D printing, and its enhanced technological capacities benefit professors and students focused on advanced design projects and skills.

In'Tech Industries is a supplier of rapid prototyping/additive manufacturing, engineeringservices, tooling services and injection moulding. It wanted to expand its 3D printing offerings to create a bridge-to-production solution for its OEM customers.

In'Tech claims that the automated workflow of the Stratasys Continuous Build 3D Demonstrator has enabled it to offer same-day or next-day delivery of quantities of identical or mixed parts, helping the company improve customer service without the need for additional staff.

In'Tech claims that the automated workflow of the Stratasys Continuous Build 3D Demonstrator has enabled it to offer same-day or next-day delivery of quantities of identical or mixed parts, helping the company improve customer service without the need for additional staff.

FATHOM is an advanced manufacturer with expertise in additive technologies. It has used the Continuous Build 3D Demonstrator to push the limits of additive manufacturing. Many of its customers have adopted digital fabrication beyond prototyping as a means of production and are using proven additive technologies like Fused Deposition Modelling (FDM) for high-value, end-use applications. A six-cell configuration has been installed in-house to increase throughput and enable a greater volume of FDM parts within a shorter lead-time.

Stratasys built the 3D Print production platform around its Fortus FDM technology that is already being used in industry.

Kelesoglu says: “Fortus systems are being used for manufacturing flight-ready parts for aerospace applications. In factories, the systems are producing tools, jigs, and fixtures. It’s also being used in vertical industry segments, including automotive and medical, among others.

“The system is based on two very significant pillars of Stratasys: one is the Fortus FDM print engine technology that is known for its reliability and accuracy, the second is the GrabCAD cloud-based 3D printing management software, which enables very smooth user interface with high quality. The software controls the build and there are algorithms to optimise the queue and load balance, monitor printer availability and manage throughput.”

The move from purely prototyping to actual manufacturing has already begun, but for the most part, in small steps. For example, companies like Boeing have experimented with it on a small scale for customised pieces.

Stratasys’ Continuous Build 3D Demonstrator could mark a shift in scale and speed for companies looking at this technology as an alternative to more traditional methods like injection moulding.

Wide scale manufacturing by 3D printers still seems a way off right now, but if Stratasys and competitors like HP Enterprise and 3D Systems are able to reduce the costs, it could serve as a key alternative to other more traditional manufacturing models like injection moulding.

Certainly, it offers the ability to create much more customisable parts than traditional methods and could even help return local manufacturing for hardware start-ups, as a more lightweight and flexible system.

HP announced more details to its open platform for 3D printing materials and production-ready applications, by adding it would lower the cost of advanced 3D printing materials, drive speed and make performance improvements. Tim Weber, global head of 3D materials and advanced applications at HP, says: “Our growing certified partner network and leading-edge lab facilities are a testament to the progress we are making in spearheading a dynamic community of collaborators focused on delivering the most innovative and production-ready 3D printing solutions.” In collaboration with SIGMADESIGN, HP offers a Materials Development Kit (MDK) for 3D printing materials, ensuring a simplified certification and testing process. It will enable companies to certify their materials to quickly test 3D powder spread-ability and compatibility with HP Jet Fusion 3D printers prior to submitting the materials to HP for testing. Bill Huseby, president and CEO, SIGMADESIGN, says: “Many companies do not have the internal capabilities to execute their 3D printing vision. We are proud to provide world class foundational tools such as the MDK and in-depth design expertise for organisations ready to innovate.” |

HP’s open platform

HP’s open platform