Below a certain temperature superconductors can ‘freeze’ the field of a permanent magnet at a predefined distance and can thus hold it in suspension. The resulting air gap remains stable in any spatial position. By this means, objects can be stored contact-free without any control technology and be moved with minimal expenditure of energy. Its dust- and abrasion-free operation makes it suitable for the transport of items in cleanroom environments.

Georg Berner, head of Strategic Corporate Development, Group Holding Festo, said: “There are already various solutions for storing and moving objects without contact. But only with superconductivity is it possible at the same time to execute a rotation through 360° in any spatial direction.”

Superconducting systems are said to be suitable for bigger loads and can even work through walls and in all spatial planes across their definable hover gap. This enables objects to be handled in protected and enclosed spaces or through cladding. Areas prone to contamination or which are difficult to clean can thus be protected using smooth and easy-to-clean surfaces. According to Festo, if non-magnetic substances penetrate the bearing, the bearing and guiding function is not impaired, which also allows it to be used in highly contaminated areas.

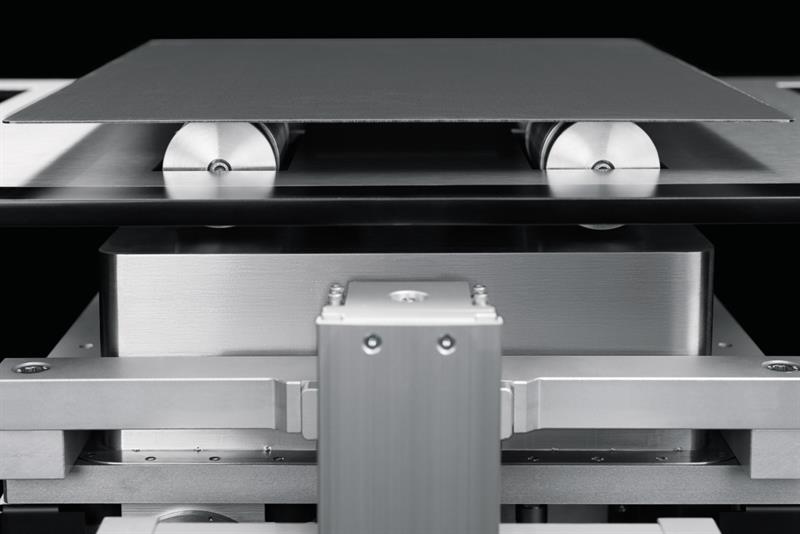

In the SupraCarrier two cryostats with superconductors are mounted on an electrical axis, above each of which two magnetic transport rollers are held in suspension. A flat workpiece carrier rests on the rollers. The axis moves the superconductor elements horizontally. Between these and the suspended rollers is a cover plate with openings through which the rollers are retracted when the cryostats are lowered; the workpiece carrier then lies on top of the cover plate.

In the SupraCarrier two cryostats with superconductors are mounted on an electrical axis, above each of which two magnetic transport rollers are held in suspension. A flat workpiece carrier rests on the rollers. The axis moves the superconductor elements horizontally. Between these and the suspended rollers is a cover plate with openings through which the rollers are retracted when the cryostats are lowered; the workpiece carrier then lies on top of the cover plate.

Suspended transport rollers such as these could be used to move flat, non-ferromagnetic products of all sizes. The conveyor unit does not require lubricants and is very easy to clean – the cover plate protects the automation modules from soiling, and the passive rollers can be removed and cleaned separately from the system either chemically or by means of heat. Superconductor technology also has further positive characteristics: the application is almost maintenance-free and highly durable; it operates silently and the air gap has an insulating effect.

Festo is now cooperating with partners and customers to identify specific applications for the technology. Berner added: “We are not merely showing impressive levitation effects and the opportunities offered by superconductor technology, but are actively discussing their potential together with the automation industry. We are currently working towards initiating our first pilot projects.”