Ultrasonic welding at prototype stage is being increasingly requested. It's a secondary process that's suited for testing and development especially when parts need functional testing in production intent material. At RP Technologies, we've developed a close partnership with our trusted supplier Sonics and Materials (UK) Ltd, meaning we can now provide this service for prototype and low volume production projects.

What is Ultrasonic welding?

Ultrasonic welding is a technique where high-frequency ultrasonic acoustic vibrations are applied to components being held together under pressure to create a solid-state weld. The process converts high frequency energy into high frequency mechanical energy, which causes heat and friction to melt the plastic which then flows together to create a solid weld.

Typical applications for this type of welding is automotive valves and bodies, medical devices, toys, electronics and appliances as the process is very clean, fast and precise. Ultrasonic welding is often chosen when parts are too complex or expensive to be moulded in one piece.

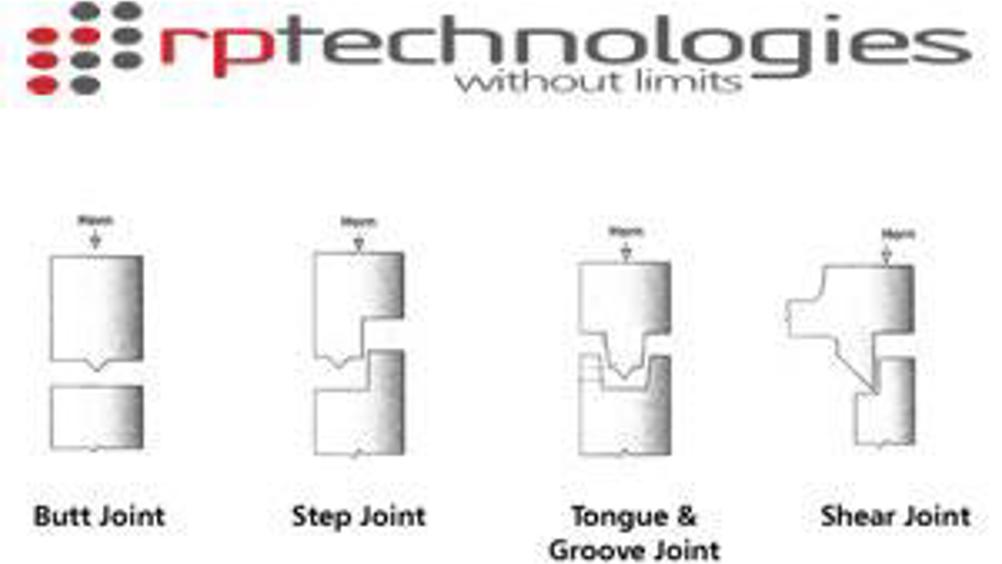

There are a few design considerations and different joint designs to consider when choosing ultrasonic welding, further details can be found on our website. RP will offer advice for each project individually to make recommendations suited to the customer design and final application requirements.

What thermoplastic materials are suitable for Ultrasonic welding?

Most thermoplastic materials can be welded using the ultrasonic welding process however some polymers are easier to weld due to their molecular structure.

Different joint designs suit different materials, the energy director is the most common design for amorphous materials, however in some cases it might not produce the results needed with semi-crystalline resins such as nylon, acetal, polypropylene, polyethylene and thermoplastic polyester. A shear joint is recommended for these resins where the geometry allows.

Leak and Strength Testing

Depending on the application that the welded components are needed for, leak or strength testing can be critical for part functionality. We can carry out leak and strength testing to ensure the final component meets customer requirements.

For further information about design considerations and different types of joint design please visit our website www.rptechnologies.co.uk/news