Four major assembly methods exist in today's manufacturing environment: Thermal methods such as spot or overlap welding; Mechanical fasteners such as bolts, screws, or rivets; Double-sided tapes; and Liquid adhesives.

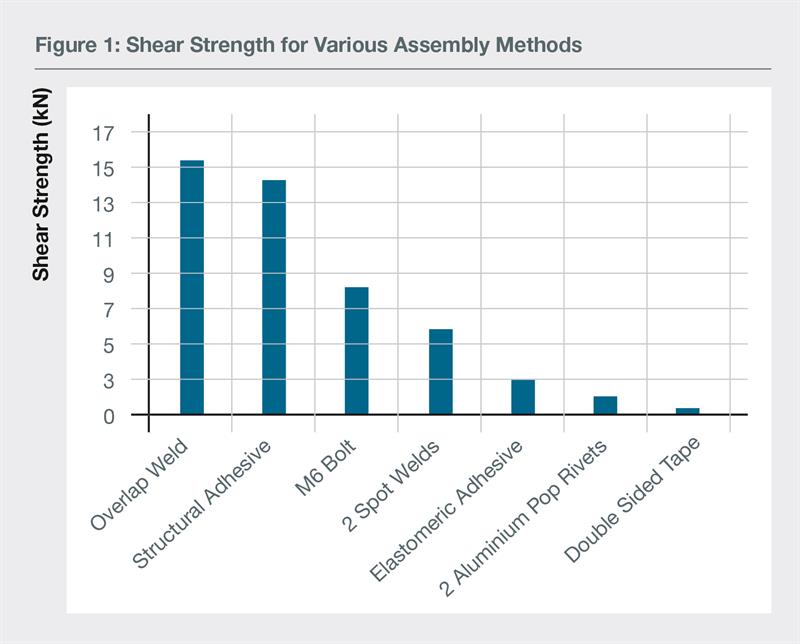

The first three assembly methods in the list above are considered 'instant' assembly methods. All four of these methods are used to varying degrees of effectiveness depending on the final application, end-use requirements, and environmental constraints such as weather, moisture, salt, or chemicals. Figure 1 shows an overview of the shear strength performance over a 645 mm² fastening area for these assembly methods.

As shown in this chart, overlap welds and structural adhesives are the strongest assembly methods available. Strength drops off dramatically using bolts, spot welds, flexible adhesives, pop rivets, and double-sided adhesive tape. For some applications, double-sided tape may provide adequate strength, but a blend of adequate strength and lowest overall cost is the target for all applications.

In many industries, structural adhesives are replacing or augmenting instant assembly methods because they can lower production costs, improve product performance and aesthetics, and reduce overall assembly-time requirements.

Adhesives offer many benefits over mechanical and thermal methods of assembly. They distribute stress load evenly over a broad area, reducing stress on a joint. Adhesives are applied inside the joint and are nearly invisible within the assembly. They can resist flex and vibrational stresses, and form a seal as well as a bond to protect joints from corrosion. Some adhesives can fill large gaps. They join irregularly shaped surfaces more easily than mechanical or thermal fastening, minimally increase the weight of an assembly, create virtually no change in part dimensions or geometry, and quickly and easily bond dissimilar substrates and heat-sensitive materials.

Since adhesives are liquids prior to curing, application and assembly can be easily automated. Bonding requires fewer skilled workers and can be up to twenty times faster than welding. Structural adhesives do not distort metals or require reworking of the metal after application, a significant advantage over the grinding and abrading required to generate a smooth welded finish.

However, adhesives also have several limitations. They must achieve handling strength prior to moving an assembly, a process that can take seconds to hours. Adhesives also cannot be easily disassembled for rework, repair, or upgrades, and they add to the number of chemicals used within the plant environment.

The True Costs of Thermal Joining

Once a welding process is completed, the resulting assembly immediately has full strength. Thermal joining is widely acknowledged as an expensive assembly process that requires specialised, skilled labour and extensive time depending on the size of the weld area. In addition, manufacturers must also consider other costs involved, such as equipment, filler metals, gas, energy, and the time it takes to complete the welding process.

Welded joints are often non-uniform and lack the clean aesthetics desired for high-end applications. Once welding has been completed, most joints must be cleaned up, a time-consuming process where weld seams are ground and polished to meet aesthetic requirements. To reduce the time involved with welding, manufacturers may choose stitch or spot welds, but will sacrifice some strength and will still have to invest time in cleaning up. Welded parts are also very difficult to disassemble.

The true costs of mechanical fastening

Assembly using mechanical fasteners such as bolts, rivets, and screws is also considered to be 'instant'. However, all mechanical methods of assembly are expensive, requiring labour to drill holes and insert fasteners. Manufacturers must keep an extensive inventory of fasteners on hand, and assembly with fasteners is time consuming.

Fasteners do not distribute loads over the full area of attachment; rather, they concentrate stress at the fastener site. This concentrated stress often results in substrate failure just above the fastener hole or failure of the fastener itself.

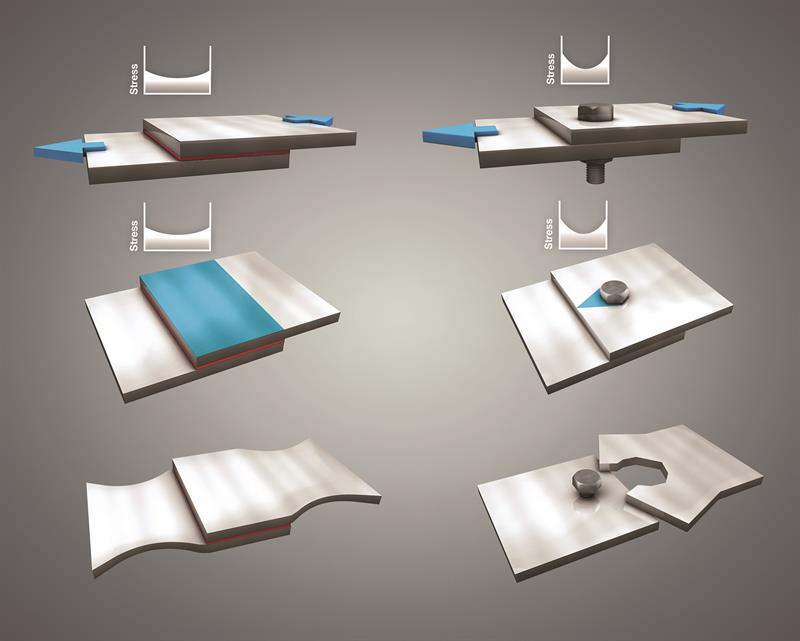

Figure 2 illustrates the distribution of stress, often an overlooked concept in the fundamental design process.

The left-hand side shows the bonded joint. The blue arrows represent the shear force applied. The leading edge of the joint has a slightly elevated level of stress than the middle, but the overall force is distributed across the entire bond area, spreading out the load. In many cases, this can lead to 'necking' or stretching of the substrate as illustrated in the bottom left image. The bolted joint is also shown on the right-hand side, with the shear stress represented by the red arrows. In this instance, the entire force applied to the joint is concentrated on the bolt. This concentration of stress leads to failure of the joint at approximately half the final strength of the bonded assembly. In addition, the holes drilled for fasteners can create leak paths, a starting point for corrosion.

The true costs of double-sided tapes

While double-sided adhesive tapes are not considered a high-strength assembly method, they do deliver an instant bond. Application of double-sided adhesives tape is a multi-step process, requiring at least two additional processing steps and takes approximately 20% more time than liquid adhesive application.

Double-sided tapes require complete removal of surface contaminants if performance is not to suffer. While contamination does result in a drop in strength with structural adhesives, they drastically outperform double-sided tapes, even on clean surfaces. Double-sided tapes display a complete performance failure when used on oily surfaces.

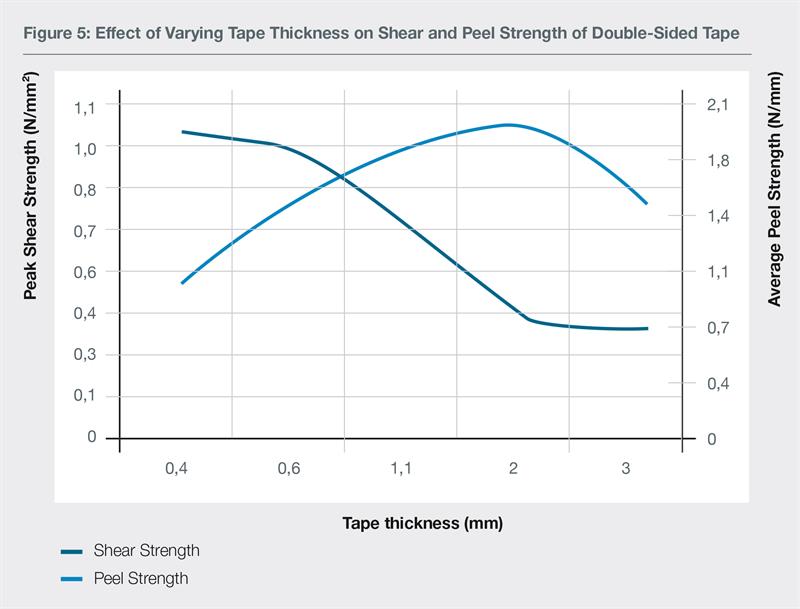

For filling large gaps, tapes are offered in a variety of thicknesses and can be an effective assembly option if gap width is consistent. As gap width increases, the shear strength of a double-sided tape can drop more than 50%. However, peel strength can increase by approximately 100%. In order to maximize shear and peel strength, Figure 3 shows that tape thickness should be approximately 0.8mm.

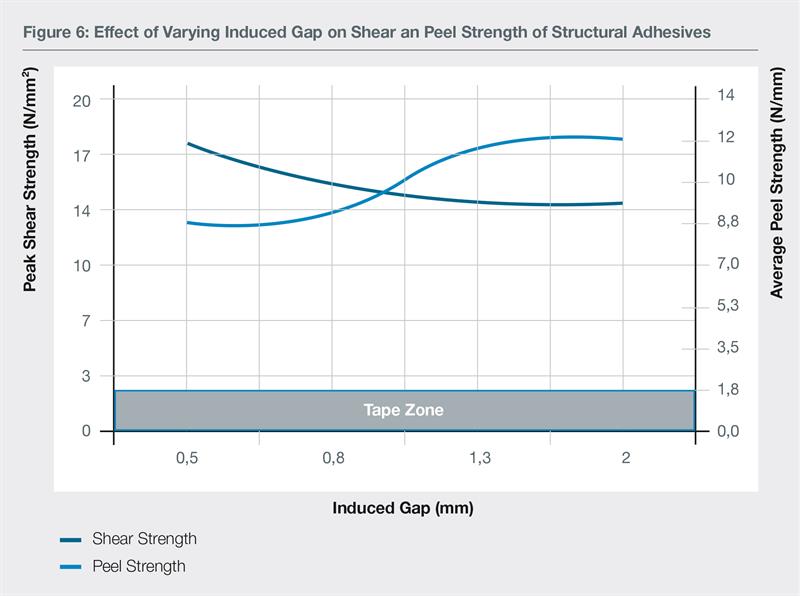

Liquid structural adhesives have a similar relationship, which can be seen in Figure 4, but the drop in shear strength with widening gaps is not as drastic (approximately 15%). Liquid adhesives offer an 80% increase in peel strength as the gap increases, and shear strength is almost 20 times greater. The peel strength values were ten times higher in some cases. Since structural adhesives are so strong, the effect of gaps is not a major consideration when designing an assembly, but should be considered more carefully when using double-sided tapes.

Assembly applications with structural adhesives

Recent advances in structural adhesive technology have dramatically expanded the scope of potential bonding applications to include hard-to-bond substrates, such as galvanized steel and polyolefins, including polyethylene and polypropylene.

On specialty vehicles such as trailers, truck bodies, buses, and construction equipment, structural adhesives are used to assemble frames, panels, booms, and cabs made of metal, plastic, and composites. In moist end-use environments such as tubs and spas, these adhesives attach galvanized steel frames to fiberglass and ABS tubs. On signs and displays exposed to environmental elements, adhesives attach metals, plastics, and composites, creating a unique appearance for the customer.

Tom Buckley is market application engineer, Henkel Corporation.

Market report According to a report from Research and Markets, the market for structural adhesives is estimated to reach around $24.20 billion by value by 2020, signifying a CAGR of around 7.71% between 2015 and 2020. The report identifies and analyses the important applications which include automotive, aerospace, building and construction, marine, rail, wind, and truck and bus. It says wind, automotive, and aerospace applications are expected to show excellent growth in the future due to the urbanisation and growing government initatives. |