Like supersonic passenger airliners, interest in spaceflight has fallen out of favour with government, which questions its value for money in these tough economic times. For all its grace though, the Shuttle was never quite able to live up to expectation. While reuseable, it required considerable rebuild, inspection and maintenance after every flight and didn’t deliver the leap forward everyone hoped.

While engineers are still fascinated by these machines, catastrophic failures and skyrocketing maintenance costs have meant those holding the purse strings have chosen to take a few technological steps back, to more simplistic technologies that are easier to manage… hence slower airliners and the return of small crew carrying modules placed at the top of giant rockets. The next generation is going back to the rocketship and taking inspiration from the Saturn V era.

Cue the development of Nasa’s Space Launch System (SLS). Of course ‘simplistic’ is used with a grain of salt: we are talking rocket science after all. Space flight is notoriously difficult and just getting in to orbit is a huge challenge. Breaking orbit – i.e. breaking free of the Earth’s gravity to go off into space – is a mind boggling endeavour.

Nasa’s SLS, once developed though, will be able to do just that and will be the most powerful rocket ever launched. It hopes to bring man a step closer to returning to the moon and even reaching Mars. So, after five years of hiatus since the Shuttles’ retirement, when can we expect a launch?

“We will keep the teams working toward a more ambitious readiness date and will be ready no later than November 2018,” said William Gerstenmaier, associate administrator for the human explorations and operations mission directorate at Nasa Headquarters.

Design verification

The initial SLS configuration will be powered by twin solid rocket boosters and four liquid-fuel cryogenic Aerojet Rocketdyne RS-25 rocket engines – the same as those previously used on the Space Shuttle.

For its first flight test, the SLS will be configured for a 70 tonnes lift capacity and carry the uncrewed Orion crew module beyond Low Earth Orbit (LEO). However, in its most powerful configuration, the SLS will provide a lift capability of 130 tonnes and enable missions farther into the solar system, including asteroids, the Moon and even Mars.

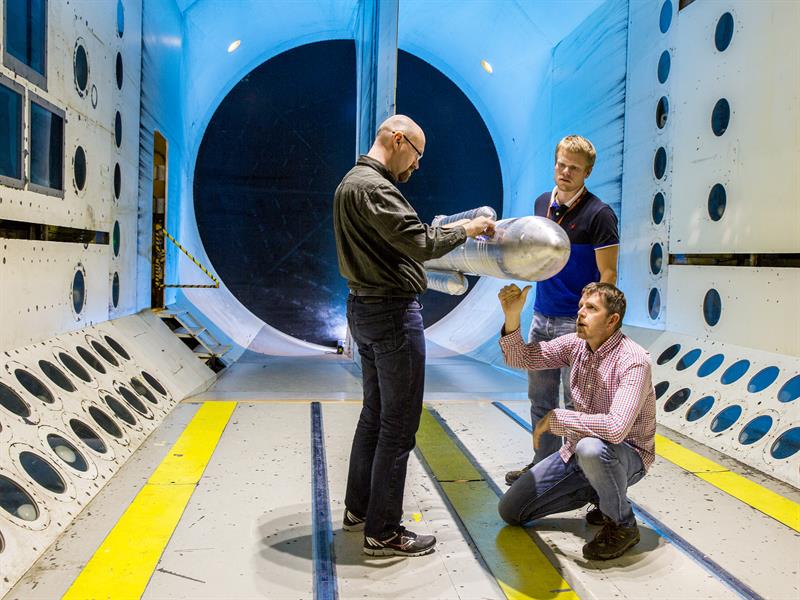

The design is well beyond the initial concept phase and engineers are deep in to the detail. Part of the development is extensive work in qualifying design predictions made in simulation models with test data from wind tunnels, and then using the data to further refine the SLS design.

A scale model of the upgraded rocket in crew and cargo configurations was carefully positioned in supersonic wind tunnels. As the launch phase is arguably the most important part, engineers need to carefully measure the forces and loads that the air induces on the launch vehicle as it accelerates through every phase of the atmosphere.

Dr John Blevins, SLS lead engineer for aerodynamics and acoustics, said: “All the critical aerodynamic environments from acceleration through the sound barrier to booster separation at more than Mach 4 are evaluated in these tests.”

As the rocket approaches the speed of sound, shockwaves build up and move along different points of the launch vehicle. These cause buffeting, shaking, vibration and unsteady loads that could easily result in damage or change the rocket’s trajectory.

Defining the location and behaviour of these shockwaves is difficult to predict with computational fluid dynamics as they continue to change angle and strength as the vehicle accelerates. To assess the impact, the aerodynamics team is developing an optical measurement method involving Unsteady Pressure Sensitive Paint. During wind tunnel testing, special lights and cameras will observe changes in the paint’s fluorescence, indicating the strength of aerodynamic forces acting along different areas of the rocket or test article.

“For a lot of aero-acoustics and buffet work, we instrument the models with hundreds of pressure sensors,” said Nasa engineer, Dr Patrick Shea. “If we can start moving to more of an optical technique such as the dynamic pressure sensitive paint, it will really make good strides forward.”

The thermal effect

It is not just shockwaves that the designers must contend with, as the vehicle reaches speeds of more than 17,000mph in its 8.5 minute flight, its outer surface will dramatically heat up. The phenomenon known as aerodynamic heating is caused by friction created between the air and the rocket’s surface as it accelerates through the atmosphere.

Typically, aerodynamic heating is most significant for the SLS vehicle during the second minute of flight, a time period in which the vehicle accelerates from approximately Mach 1 to Mach 4.5. Nasa uses a special type of wind tunnel to generate airflow at both supersonic and hypersonic flight conditions, matching the rocket’s environment during ascent including temperature, pressure and velocity. The tests last just 40 milliseconds each, but reach speeds of Mach 3.5-5.

Test measurements are made in three different ways. First, pressure and aerodynamic heating are measured at nearly 200 individual sensor locations on the test model. This is combined with Schlieren imaging, an optical technique for visualising supersonic flow around objects. Finally, temperature-sensitive paint is applied to critical regions of the test model to provide additional insight into the heating distribution.

The SLS rocket configuration, with boosters attached, is tested at zero and 5° angles of attack. At 0° the airflow is coming parallel to the vehicle. The boosters are removed from the model and the remaining core stage is tested again at higher angles of attack between 15-20°, an orientation observed following booster separation in nominal flight.

“Our primary objective for the test series is to gather conclusive aerodynamic heating model validation data, both before and after booster separation,” concluded Chris Morris, aerothermodynamics team lead at Nasa’s Marshall Space Flight Center. “These tests give us a lot of insight into how well our engineering and computer models do at predicting aerodynamic heating on the vehicle. The data is very important for certifying that the thermal protection system on the rocket will be sufficient to protect the rocket’s structure and vital systems inside it.”

Fast Facts Height: 111m |