Visual inspections may be sufficient for some manufacturing processes, but there are certain applications where inspections must be more comprehensive. Achieving a detailed examination is possible using 3D measurement technologies. A variety of techniques are available, which can be loosely split into two types — contact and non-contact.

Optical 3D scanning methods are a popular method of non-contact measurement. Typically performed using laser scanner or fringe projection systems, optical scans can measure thousands of points per second for a quick, complete scan of the finished product.

But not all products are best suited to optical methods. Items made from materials with reflective or translucent properties can be difficult to measure using light-based methods. While coating sprays are available to allow optical-based measurements, applying and removing this layer can create unwanted additional steps in the manufacturing process.

An alternative option is to use a coordinate measuring machine. Generally regarded as the most accurate form of 3D measurement, these machines can take readings with a tolerance of just one micron.

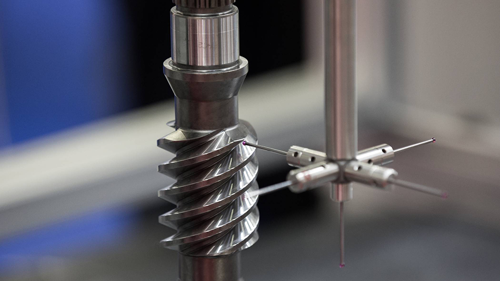

CMMs rely on a probe with a ball-shaped measuring tip that’s positioned onto mapped reference points. It’s possible to manipulate the probe not only around the object, but also within it for access to hard-to-reach cavities. However, there are some disadvantages to CMMs. This includes the long measurement time caused by physically moving the probe around the product.

This is where multisensor methods come into play. By using a traditional CMM machine alongside an optical technique like laser scanning, manufacturers can make the best of both approaches.

Whichever method is used for imaging, it’s clear that they all rely on one thing — the accurate positioning of the sensor elements. When selecting a drive system for such applications, it’s crucial that the precision of these small DC motors is on par with what the final measurement technology is expected to deliver. This includes the use of encoders, which can generate position signals based on the motor shaft rotation or linear movement. Crucial to allowing achieving precise positioning, these also allow for closed loop control of the motor.