New Levels of Assembly Speed and Flexibility at a Sensible Price

The most significant and common factor that slows down the assembly process is human. The repeated requirement for the operator to reach into a box, pick up a rivet, insert it into the nose of the tool and then install it.

The new Z-AR automatic rivet system removes that continuous requirement.

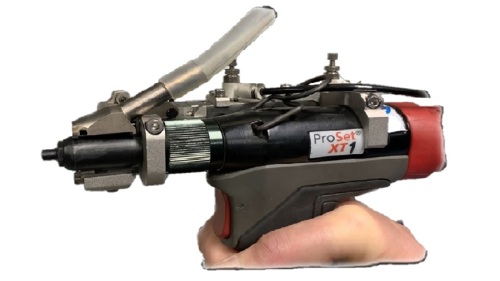

Its bowl feeder holds up to 1,000 rivets at a time, and by utilising specially adapted Stanley XT1 or XT2 tools attached to the Z-AR bowl feeder and control unit, rivets are fed to the tool nose tip at the rate of 60 or more per minute.

With the Z-AR, rivet handling by the tool operator is almost completely eliminated, and downtime is significantly reduced.

An Almost Instant Rivet Feed

After each rivet is installed, the PLC controlled mechanism feeds a new rivet from the bowl feeder to the nose tip almost instantly. The speed of assembly is only limited by the dexterity of the tool operator.

The spent stems are automatically ejected from the tool and collected in a storage container within the control unit for quick and easy disposal or recycling.

True Continuous-Feed Riveting Now Available for Manufacturers of all Sizes

The Stanley XT1 and XT2 tools sit comfortably in hand, are fast and offer excellent reliability. The transfer mechanism is easy to remove from the tool, and as the tools use readily available parts, routine maintenance is quick, cost-effective and straightforward.

The Z-AR system can accommodate most standard rivet types between 3.0 and 5.0mm diameter, and all rivet materials can be accommodated including aluminium, copper, steel and A2 and A4 stainless steel.

The flexible umbilical allows 360° riveting in any direction making the Z-AR suitable for all manufacturing environments.

Full technical details and specifications can be found here: Z-AR Auto Feed Riveting System full details.

A New Riveting System That Couldn’t Be Simpler or Faster

Discussing the Z-AR Auto Feed Riveting System, Zygology Sales Director, Richard Avery said, “One of the common questions we get is how to speed up the riveting process. The most significant factor that slows things down is the need for the operator to reach into a box, pick up a rivet, carefully insert it into the tool's nose, and then install it - again and again.

“This tool takes all the fiddling around out of the equation. It’s loaded with up to 1,000 rivets and keeps feeding them on demand until they run out. You just then need to refill the feed bowl and repeat.

“Thanks to the new Z-AR, the riveting process couldn’t be simpler or faster.”

Get In Touch with Us Today To Speed Up Your Riveting Process

The Z-AR Auto Feed Riveting System will speed up your riveting process and as it’s only available at Zygology, we are ideally positioned to help your processes.

To discuss how the new Z-AR Auto Feed Riveting System can increase your efficiency and flexibility whilst reducing your manufacturing lead times and reduced downtime, get in touch with our friendly team of experts today on 0808 123 1221 or email sales@zygology.com.

You can also discover more about the Z-AR Auto Feed Riveting System here.

Zygology – The fastening experts for over 40 years!

We’re engineering product specialists that understand the practical applications of our fasteners and tools to provide you with bespoke solutions to your assembly requirements.

Our commitment to providing the best service and quality management is backed up by our ISO 9001 and UKAS Accreditations and we will always give the best advice we can - even if it means that we end up recommending a competing technology.

Combining friendly service and expert advice with competitive prices and excellent stock availability, our assembly solutions help you reduce your production costs and increase