Among these is a new range of right-angled planetary gearboxes is now available from Motor Technology for a wide range of industrial applications. Manufactured by Italian firm, Tramec, the TEP range is based on the company’s long-established EP range of general-purpose planetary gearboxes.

Right-angled gearboxes are frequently used where there are space constraints on a machine, often machines with high axis counts, such as slitters and winders, printing and packaging machines, handling and robotics, etc.

Currently available in four frame sizes, 55, 75, 90, and 120, in one and two stage configurations. Single stage versions offer ratios from 3:1 to 10:1, and two stage versions offer ratios from 12:1 to 100:1.

Backlash ranges from 12-17 arcminutes for the single stage and 15-20 arcminutes for the two-stage versions. Gearbox efficiency is 94% for the single-stage type and 91% for the two stage.

The gearboxes also perform well in terms of noise generated during operation with levels between 65 to 70dB at 3000rpm input speed. Gearbox output torque is up to 180Nm nominal, 290Nm peak, and with an E-Stop torque of 600Nm.

The gearboxes are flange compatible with Tramec’s EP series and also offer alternative shaft and output flange options. A wide range of motor adapters are available for typical servo, stepper, DC and AC motors.

Another innovation comes from Motion Control Products, which has introduced compact high torque motors with integral strain-wave (harmonic) gearboxes.

Offering high levels of torque and precision, the latest torque motors have an integral strain wave (harmonic) gearbox. With high efficiencies and compact sizes, they are available in four series: MAS, MAT, MAH and MGM.

The all-in-one MGM series has an integral torque motor, encoder, brake and servo drive. Delivering a high precision of up to 60 arcseconds, their high torque of up to 557Nm suits them for a host of applications demanding low noise, high torque and precision control, such as collaborative robot applications for loads of up to 25kg. Integrated servo drives for EtherCAT or CANOpen enable the units to interface with most mainstream controllers on the market. A hollow shaft simplifies system design by allowing the passage of cables, pipework etc.

The other series of low-cogging, low noise motors have an integrated strain wave gearbox and frameless motor with a range of encoder options. One series is the MAH, which has a standard hollow shaft and frame sizes from 60mm to 145mm diameter. Rated torques of up to 800Nm are available and precision is up to 30 arcseconds.

The MAT series has a wider hollow shaft and offers a precision of up to 40 arcseconds, while the MAS series have a solid shaft and a precision of up to 50 arcseconds.

Across the whole series, all the models are flexible, reliable, low maintenance and compact. Gear ratios are available from 51:1 to up to 161:1. All models are fully enclosed and self-cooled and can be specified with IP67 ingress protection when operation is required in harsh environments.

Standard input voltages are 48VDC, 110VAC and 220VAC, and input voltages can be customised on request, as can the torque, etc.

As well as robotics and factory automation, applications for the versatile motors include electronic and semiconductor equipment, medical equipment, precision measuring instruments, machine tools, laser processing and spray-painting equipment.

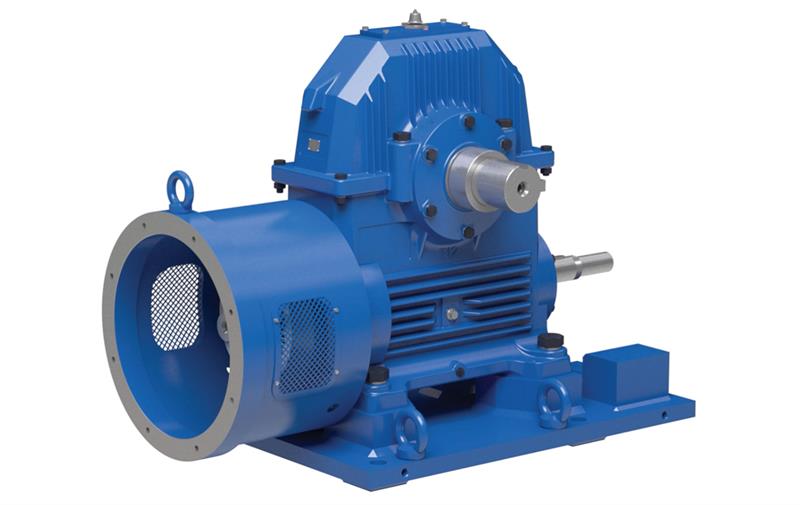

Renold Gears has launched a leak-free technology kit for heavy-duty gearboxes that can either be supplied with new units or retrofitted to existing ones.

After a lengthy development process, extensive testing of a gearbox fitted with the new technology showed that all components received sufficient lubrication and, most importantly, without any oil leakage. The operational temperatures were also found to be significantly lower, indicating reduced power losses of up to 14%.

Overall the results of the tests showed that the new solution operated better than the standard configuration. After delivery to Tubelines a gearbox fitted with the new leak-free kit passed all testing protocols and was eventually installed on an escalator where it has been operating satisfactorily at a busy station without any issues.

Commenting on the project, Roger Godson, of Renold Gears, said: ‘We’re very proud to have been invited to develop a leak-free gearbox solution for Tubelines and to have made a contribution to significantly reducing the maintenance of escalator drives on the London Underground.’

Whilst initially designed for heavy load escalators at underground stations the new leak-free gearbox technology is perfectly suited to a wide range of heavy-duty industrial applications including, conveying, mining and quarrying, cement manufacture, pumping, water and wastewater treatment, metal manufacture and power generation, etc.

New manual gearbox enables CO2 savings Volkswagen has developed a new state-of-the-art manual gearbox: The MQ281, as it is known, works efficiently and saves up to five grams of CO2 per kilometre depending on the engine-gearbox combination. The new Passat is the first vehicle to be equipped with the MQ281, followed by almost all vehicle classes of the Volkswagen Group. Only slight modifications were sufficient to improve efficiency and consumption with a huge impact on emissions and the environment. Although they function unobtrusively, manual gearboxes have a significant share of the gearbox market worldwide due to a high installation rate.

It is based on a 2.5 shaft concept and boasts a high gear spread of maximum 7.89. On the one hand, this guarantees good driving off performance – even for heavy vehicles with large wheels – and facilitates, on the other hand, “downspeeding”, which is (fuel-saving) driving in high gears with low engine speed. Material use and its distribution for the gearbox housing was also optimised. With the aid of a further virtual development tool, a strength- optimised housing structure could be designed. The new housing supports the noise requirements of today (avoidance of undesired secondary noises) and therefore ensures improved driving comfort through less audible and noticeable vibrations in the vehicle. As is the case with many Volkswagen gearboxes, the MQ281 is produced in-house. Ramp-up is currently underway in the factories in Barcelona (Spain) and Córdoba (Argentina). |

The trend towards vehicles from the SUV segment with large-diameter wheels places high demands on the gearbox. “With the MQ281, we have developed a highly efficient manual gearbox that reliably meets these demands – and is soon to be introduced into a number of vehicle classes in the volume segment,” explains Helmut Göbbels, head of manual gearbox and four-wheel drive development at Volkswagen. The MQ281 has a torque spectrum of 200 to 340 newton metres, which means it completely or partially supersedes the current Volkswagen gearbox designs with the internal designations MQ250 and MQ350 respectively.

The trend towards vehicles from the SUV segment with large-diameter wheels places high demands on the gearbox. “With the MQ281, we have developed a highly efficient manual gearbox that reliably meets these demands – and is soon to be introduced into a number of vehicle classes in the volume segment,” explains Helmut Göbbels, head of manual gearbox and four-wheel drive development at Volkswagen. The MQ281 has a torque spectrum of 200 to 340 newton metres, which means it completely or partially supersedes the current Volkswagen gearbox designs with the internal designations MQ250 and MQ350 respectively.