High Power Density

Within a compact unit, maxon DC motors provide a continuous torque rating of up to 1Nm. This can be increased using a gearhead. The ironless copper winding allows for a great volume/power ratio.

Compact units with high performance are beneficial for applications such as robotic arms used to assist humans with consistent heavy loads in warehouses (maxon’s RE 40 and RE 65 DC motors). The RE65 offers a nominal torque of approximately 900mNm and can be overloaded depending on the duty cycle.

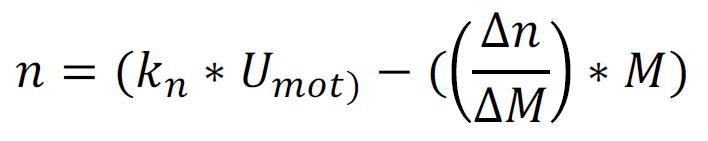

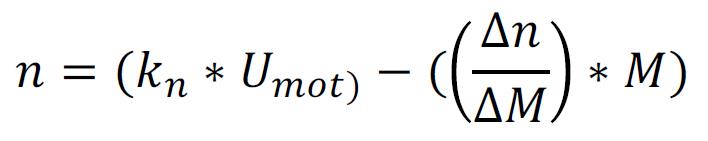

High power density refers to the maximum torque and speed rating within a small volume and the speed/torque gradient of the motor. This defines the strength of the motor when additional load is applied; for every mNm of torque applied, the speed output of the motor is decreased.

Where: n = Output speed (under load) (rpm), kn = Speed constant (rpm/V), Umot = Voltage applied, Δn/ΔM = Speed/Torque gradient (rpm/mNm), M = Output torque (mNm)

maxon offers a speed/torque gradient as low as 0.306 rpm/mNm (EC-i 52 180W) that is used in direct drive applications where there is a fluctuating load.

Humanoid robots require a small powerful unit (high power density). The EC-4 pole 22 motor has a high output power as it has two pole pairs. A ceramic gearhead transmits more torque to the output shaft without causing internal wear.

High Controllability

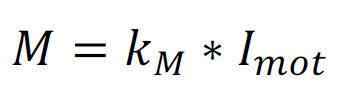

maxon DC motors offer a linear relationship between the voltage applied and the speed output, in addition to the current and torque output.

Where: n = Output speed (no load) (rpm), kn = Speed constant (rpm/V) and Umot = Voltage applied

Where: M = Output torque (mNm), kM = Torque constant (mNm/A) and Imot = Electrical current

High Acceleration

Coreless DC motors allow high acceleration, critical in pick and place systems and delta robots. In addition to low inertia, maxon offers a low mechanical time. For highly dynamic applications (constant acceleration/deceleration), a motor with low rotor inertia is fundamental.

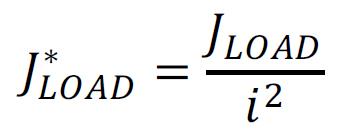

Acceleration is determined by the torque required and the inertia of the load and rotor. If the load has an inertia more than 10x rotor inertia, a gearbox is required. Using a gearbox, the motor would see a ‘reflected load inertia’.

Where: J* = Reflected load inertia (seen by motor), J = Load inertia and i = Gearbox reduction ratio

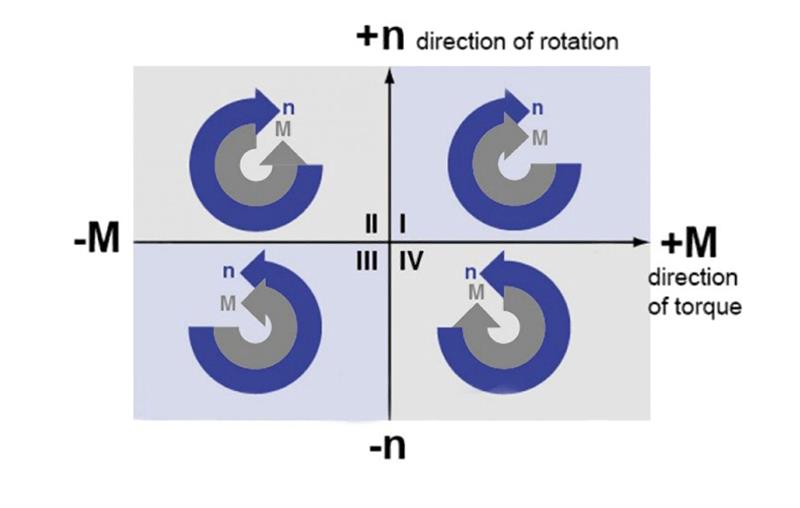

For high acceleration and deceleration, the power supply and controller should be reviewed. For deceleration torque is applied in the opposite direction to slow it to a halt. This prompts high current from the power supply and/or controller. There is also reversed energy supplied to the controller and the power supply.

4-Quadrant controllers (ESCON and EPOS) are recommended for highly dynamic applications.

Low power consumption

Portable robotic applications are operated by battery power and require a long duty cycle. When using a maxon gearhead the number of stages should be kept to a minimum as the efficiency decreases. It is best to choose a gearhead with a rated torque output comparable to the required torque output.

Highly robust

The maxon DCX and RE products have metal housing and flanges suiting them for robust applications, such as temperature, vibration and shock. They can be modified to suit specific requirements. From the BLDC range, the EC-Max has a robust steel housing.

When operating in extreme temperatures, maxon suggests -20 to 100°C. Modifications can allow the motors to operate beyond this, including adjustments to the PCB, grease and cables.

Underwater inspection robots are required to be robust and efficient. The RE40 + GP42 gearbox is the perfect combination of physical design, service life and ability to cope with high pressure.

Speed and torque requirements

For robotic applications, high torque is usually the main requirement rather than speed.If a gearhead is not suitable, maxon has high torque motors rather than high speed. maxon offers several brushless motors which are multipole, hence particularly suited towards robotic applications.

Whilst the flat motor has up to 12 pole pairs (EC 90 Flat), it has a high rotor inertia, making it unsuitable for dynamic applications that require high acceleration. Flat motors are useful for applications such as humanoid robots, where a high torque, compact unit is required, that doesn’t have a high dynamic requirement.

EC flat frameless

Robotic arms have space and weight restrictions, and high torque is required not high speed. maxon’s frameless motor can be fully integrated. It is delivered as a rotor and stator and has an open design with room for cables, that also allows for higher rates of heat dissipation, so the unit can be overloaded on an intermittent basis when required.

EC-i 30

EC-i 30

The EC-i 30 is ideal for highly dynamic applications due to low mechanical time constant and internal multipole rotor. It is a compact unit with a high-power density, offering a nominal torque of up to 110mNm. The modular system allows an increase of torque with various gearheads from the GP32 range and the 32mm spindle range. The motor offers a very low speed/torque gradient (4.07 rpm/mNm). It is compatible with a wide range of encoders, including the Encoder 16 EASY Absolute for where an absolute position is required.

Encoders in robotics

Many robotic applications consist of mechanically interdependent axes, meaning incremental encoders may not be sufficient. Incremental encoders require a homing procedure to determine the position of the motor shaft, requiring additional time.

maxon offers absolute encoders which eliminate the homing procedure. The absolute position is detected within one revolution for single turn encoders and several revolutions for multi turn encoders.

Single turn absolute encoders are suitable for direct drive rotational systems and for multi turn absolute encoders linear drive systems.

Considerations for an encoder for a robotic application:

- Counts per turn (increments)

- Accuracy

- Use of an index channel

- Use of a line driver

- Maximum supported speed

- Suitability for ambient conditions, such as dust, oil, magnetic fields etc.

In summary

While certain robotic applications seem very simple in operation, there may be very high requirements with regards to reliability, environmental conditions and the physical attributes of the motor unit. In addition to the output performance, these factors must be taken into consideration.