Firstly, let’s address the elephant in the room, who is not wearing the right gear? Who’s not handling motors with care? If a DC motor is not handled with care, it can be damaged, stopping the motor from functioning as it is designed to. If you drop a motor it could dislodge small components within it or even fracture them.

An important factor to consider is ESD (Electro-Static Discharge), which is critical for brushless motors. ESD could damage the hall sensors or encoder, rendering them useless and unable to get any feedback from the control system.

Brushless motors commutate electrically through Block or Sinusoidal commutation. Studies show that you can generate up to 15,000V in the human body so by releasing that energy you can short circuit a motor. That’s why wearing the correct gear and thinking about how you are going to handle the motor is crucial.

Before even having bought a motor some environmental conditions must have been considered. This question should have been considered beforehand: what is the ambient temperature in which the motor operates? Each motor has its own operating range and this is dictated by the heat reliability of the materials and the viscosity of the lubricant in the bearings.

If the actual ambient temperature falls outside this range, then expect failure sooner than you wanted. At low temperature, the lubricant will freeze and increase friction within the bearing causing increasing wear and excessive axial play due to shrinkage of components. You will have the same consequences operating at high temperatures, however, in this case the lubricant will become a liquid and it will run away from the areas where lubricant is needed.

Another element that might need to be considered is the humidity of the environment in which it operates. High levels of humidity can cause corrosion within the bearing which causes friction to increase, again effecting wear. This may damage the shaft and the bearings restricting the smooth rotating operation of the motor, which in turn affects speed and torque. It also leads to contamination within the drive due to the abrasive nature that is corrosion.

The motor

In DC motors, they commutate using brushes, whether it be graphite or precious metal. It is the brushes that limit the life of these motors and it is the ball bearings that limit brushless motors. The life of these brushes can be influenced by a number of factors; the use of high currents will cause massive electrical wear and high speeds will considerably impact the mechanical wear on the brushes. Extreme starts and stops, left to right operations and also excess temperature, humidity and vibration all contribute to the demise of a brushed DC motor.

Brushless motors, on the other hand, will fail once the bearing has been worn out due to previously discussed factors, but in addition, residual unbalancing and bearing load have an impact on life. There is given data for each motor which limits operating ranges, but the reality is that it is not always followed, so time and again motors fail because they are not used, or specified, as needed.

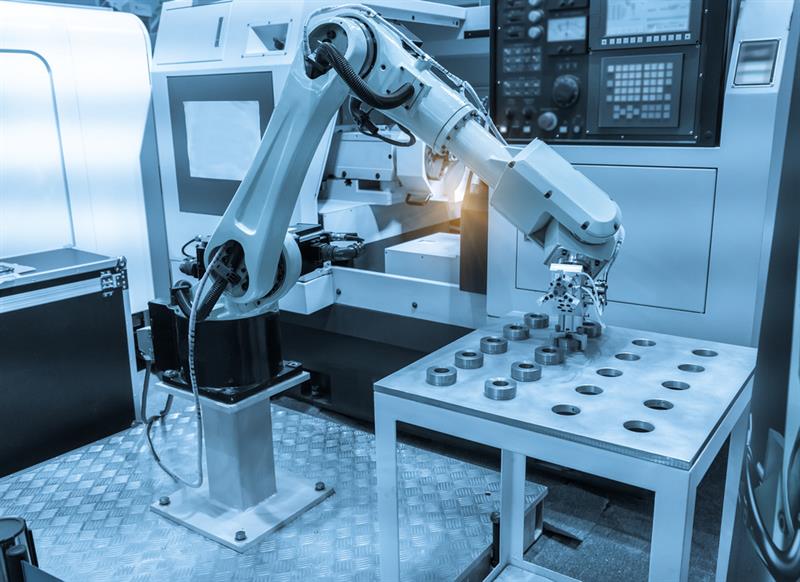

Industrial robot market booming Rapid growth within robotics is affecting markets across the board, from automotive and electronics to cosmetics and pharmaceuticals. The research, from business intelligence firm MarketsandMarkets, shows that the industrial robotics market will grow at a compound annual growth rate (CAGR) of 9.6% in the next six years. Although the highest demand is for articulated robots, other types including cartesian, parallel and collaborative are also growing rapidly.

Automation in the food and beverage sector, for example, has seen the increased use of robots in pick and place applications where advancing gripper technology, combined with improvements in motors, gears, sensors and artificial intelligence software, means that robots can carefully handle various sizes of food items. Shrinking product lifecycles in the consumer electronics market is also driving growth for desktop collaborative robots in the small parts assembly sector. Devices such as phones, tablets, wearable fitness trackers and smart watches that used to be updated once every few years now have regular 12-monthly cycles. As a result, OEMs have to start production planning for future products as soon as the current model is launched. In terms of the global market, the Asia Pacific region is expected to own the highest share of the robotics market over the next decade. This can be attributed to various factors that drive down the cost of production, including lower wages, a closer proximity to raw materials, a less stringent taxation environment and economies of scale. Although the future looks bright, this demand is causing stress on supply chains. According to figures by the Office for National Statistics every G7 country has seen productivity suffer since the 2008 financial crisis, with the UK being affected twice as hard. Countries like Germany, USA and France are leading the way in terms of output per hour worked. Staffs-based Harmonic Drive UK has seen a surge in demand for high precision gears as a result of the demand for robots. The six elements of its precision gears — zero backlash, accuracy, repeatability, high torque, compactness and low weight — make them ideal for increasingly high precision automation environments. To meet this demand, Harmonic Drive increased investment in its manufacturing setups and continuously looks at making improvements to facilities so it can deliver customer orders faster. It says, as the market continues to grow, OEMs and business leaders need to refocus their efforts and gear up to meet the demands of the robotics market. Author profile: |

The main drivers for this growth comes from two sources: increased investment in automation in a growing number of industries, and rising demand from small and medium sized businesses in developing countries.

The main drivers for this growth comes from two sources: increased investment in automation in a growing number of industries, and rising demand from small and medium sized businesses in developing countries.