“The use of CONVERGE has allowed us to run high quality in-cylinder CFD simulations,” explained Dr Werner Willems, Ford technical specialist for combustion systems. “We used CONVERGE to refine a number of features on the EcoBlue, including the shape of the combustion chamber, the piston bowl geometry and the fuel injection parameters.”

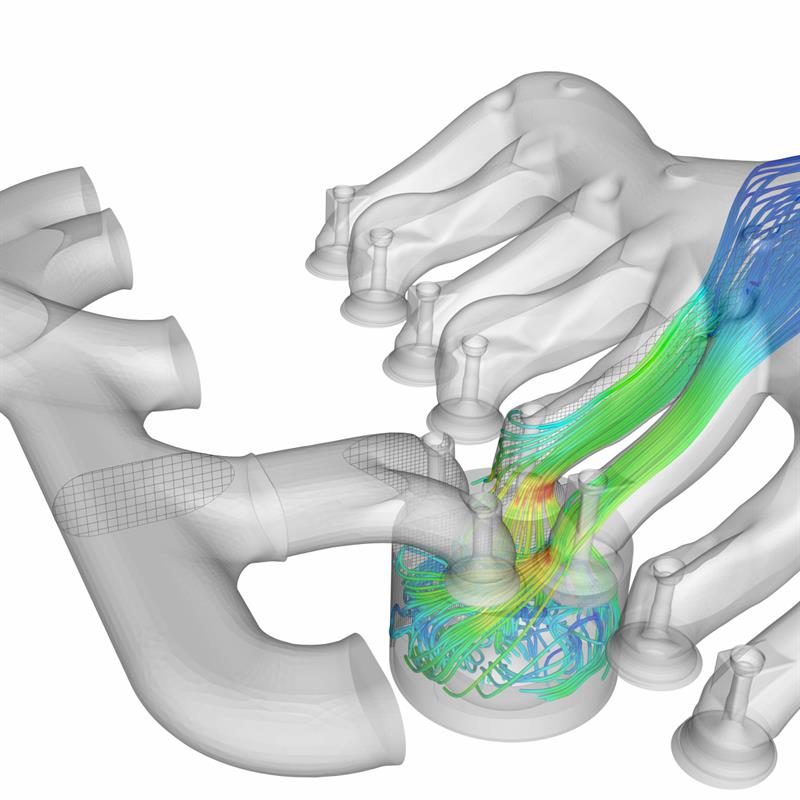

In particular, Dr Willems and his colleagues used the package during the development of the EcoBlue’s mirror-image intake ports. The symmetrical design of the integrated inlet manifold causes the air going to cylinders one and two to swirl clockwise, while the supply to cylinders three and four swirls anti-clockwise.

“The two sets of ports are essentially mirror images of each other,” explained Dr Willems. “When you have a lot of variation between the airflow you’re always focusing on getting the weakest cylinder to work properly, which means the others are being held back. Our mirrored port design improves the distribution of air between the cylinders, which reduces emissions and fuel consumption.”

“The two sets of ports are essentially mirror images of each other,” explained Dr Willems. “When you have a lot of variation between the airflow you’re always focusing on getting the weakest cylinder to work properly, which means the others are being held back. Our mirrored port design improves the distribution of air between the cylinders, which reduces emissions and fuel consumption.”

This contributes to the EcoBlue’s environmental credentials, which include a 13% reduction in fuel economy compared to its predecessor, as well as reductions in tailpipe emissions.

CFD studies are a powerful tool in engine development, but they have traditionally been a time-consuming and complex process. CONVERGE, however, automates the meshing process carried out before the simulation, reducing the amount of manual input required.

It also uses a function known as Adaptive Mesh Refinement (AMR) to regenerate the grid at each time-step, re-structuring it to accommodate changes in geometry or activity. That means that events such as valve opening and piston motion can be modelled without stretching or skewing the mesh, which would incur so-called deformation errors. More importantly, the AMR function is fully coupled with the flow and chemistry solvers, so it can automatically vary the mesh density across the model. By applying a denser mesh in more critical areas but reducing the cell count elsewhere it can improve the speed-to-accuracy ratio of the simulation.

The Ford engineers are developing the EcoBlue range, which will expand to include passenger car variants. Simulation tools such as CONVERGE look set to play a major part in this work, as the company aims to deliver improved fuel economy and reduced emissions.