The service life and reliability of piezo actuators can strongly depend on the conditions at the site of application as humidity, temperature and operating voltage have a considerable impact on performance. Since no polymer insulation exists that is absolutely impermeable, the life expectancy for conventional polymer-insulated piezo actuators can decrease dramatically at high humidity. Ingressing moisture combined with the electric field applied, can cause a short circuit between the electrodes, which will cause irreparable damage to the actuator. The service life of the piezo can also be affected by the dynamic operating forces and alternating mechanical stress conditions.

The answer lies in using the best materials, the manufacturing processes, appropriate design and the insulation material. Once that is proven to be right, there is nothing to stop their use even in the most extreme environments, like outer space.

100 billion cycles without failure

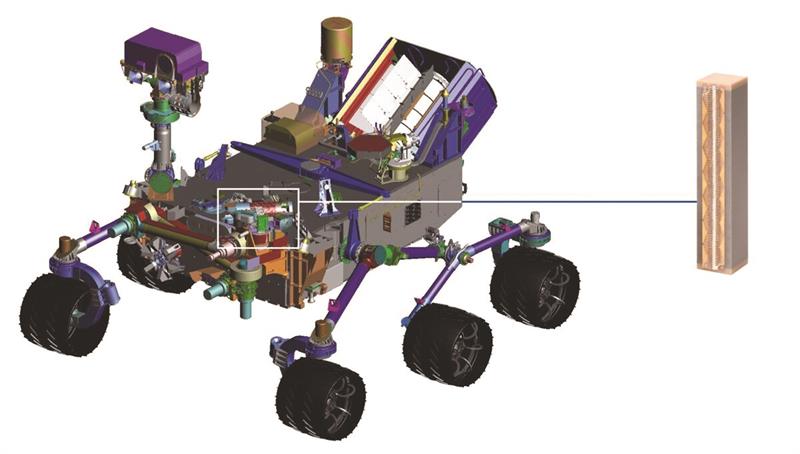

35 million miles away on Mars, PI’s PICMA multilayer piezo actuators are a component used within the NASA Curiosity Rover project. They perform oscillations of a chamber that is containing rocks and rock powder that has been scooped up from the surface of dry planet. At frequencies in the range from 0.9 to 2.2kHz, the chamber can sort particle sizes or separate rock according to density.

To be selected as a component on-board the $2.5bn project, the PI actuators service life was tested and needed to deliver incredible results. The extensive NASA performance tests showed that 96% of original deflections were still achieved after 100 billion (1011) cycles. Therefore, PI actuators were chosen to be part of the car sized robotic rover that to this day is still exploring the red planet.

Low operating voltage

The effect that the applied voltage has on the lifetime is particularly important. At 80V for example, the service life is expected to be 10 times higher than what can be expected at 100V. PICMA actuators are also a step ahead in terms of operating voltage in contrast to most conventional actuators because they achieve their nominal displacement at operating voltages significantly below 150V. This is achieved with stacking particularly thin ceramic layers.

Virtually any shape

Using modern production technologies, the multilayer actuators can be manufactured in virtually any shape. Round or triangular cross-sections with insulated center holes can also be achieved on benders, chips and stack actuators, that allows for easier integration. The individual layers are then equipped with electrodes and laminated. As with standard actuators, the ceramic is then sintered together with the inner electrodes using a cofiring process.

Assured repeatability

Stable and reliable operation is as important in space as it is here on earth. All fields of application such as white-light interferometry (WLI) which is often used for inspection tasks in LCD production or high-precision surface inspection in other manufacturing fields, require high dynamic precision positioning that delivers assured repeatable levels of accuracy. This is why, PI’s PICMA multilayer piezo actuators are often selected as the high precision positioner of choice.

PI UK is a subsidiary of the global enterprise Physik Instrumente GmbH. The PI UK office, based in Bedfordshire, is dedicated in supporting UK design engineers with their precision motion and positioning challenges and requirements. Contact one of PI’s UK based technical specialists for advice or information on how Piezo actuators or Piezo motors could enhance the accuracy, increase the reliability and reduce the overall cost, within your systems.

PI UK -01234 756360 or uk@pi.ws