Numerous aerodynamic and thermal aspects need to be considered while designing cars, trucks and all other ground vehicles. Aerodynamic drag forces need to be studied as they affect the vehicle’s fuel efficiency; underhood component cooling needs to be managed carefully to avoid damage from the engine’s heat; aeroacoustic effects have to be calculated to reduce undesirable noise; and cabin climate control needs to be optimised for passenger comfort. CFD simulation of each of these aspects requires different models and methods.

For instance, underhood thermal simulation requires detailed thermal models and fine geometric detail for underhood components, but vehicle external aerodynamic simulation does not benefit from these details. Consequently, vehicle engineering departments have separate experts specializing in each of these areas who sit in separate groups. Specialization improves quality and productivity, which is good, but there is one big problem: All the various aero-thermal aspects of a vehicle are tightly coupled with each other. Changes made to improve one have a direct, and often detrimental, effect on the others. For instance, shrinking the front grill opening to reduce aerodynamic drag throttles the underhood cooling airflow, causing heat damage to delicate plastic and rubber components near the engine. Thus, CFD analysts specializing in each of the different aero-thermal areas need to collaborate closely. However, due to different methods and models, collaboration is cumbersome. There is a great need of — and scope for — improvement.

For decades, vehicle manufacturers have wanted to perform multidisciplinary optimization (MDO): a single analysis that at once optimizes all vehicle performance factors, such as aerodynamics, wind noise, underhood cooling and others. For any design change, such as modifying the grill opening, an MDO simulation would simultaneously show the effects on aerodynamic drag, underhood component temperatures, wind noise and all other variables. However, distinct mesh requirements for the different aspects have necessitated separate simulation of these areas to date.

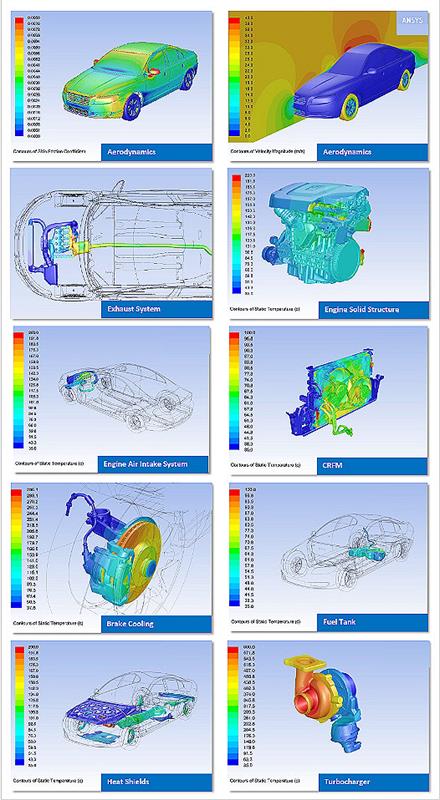

ANSYS now makes true multidisciplinary optimisation a reality, with the development of a fast and robust method of creating a common mesh model for all aero-thermal aspects of a vehicle. The method was recently demonstrated with the Volvo S80 car by a team of ANSYS automotive experts. For the first time ever, the ANSYS method successfully created a single CFD mesh model to capture full details of aerodynamics, front-end flow, full thermal underhood, cooling package, brake cooling, fuel system, engine intake and exhaust, engine structure solids, engine water jacket, turbocharger and pumps. The model incorporated 400+ solid components, including fully meshed structural components of the engine such as pistons, connecting rods, crankshaft, cylinder head, etc., in addition to underhood and underbody solids such as bushings, brackets and dozens of shells.

With such a comprehensive model, the only boundary condition inputs needed for simulation are the vehicle speed, cooling fan speed, engine cooling liquid pump speed, combustion heat source in the engine combustion chambers, and frictional heat source from the brakes. With these simple inputs, a single CFD simulation of the comprehensive model calculates aerodynamic forces and surface and body temperatures of all underhood and underbody components. This model now enables engineers to simultaneously compute the effect of any design change on all aero-thermal aspects of the vehicle and perform true multidisciplinary optimization. And, as a bonus, creating this single model requires less than half the time that is needed for creating separate meshes for aerodynamics, underhood, brake cooling, engine cooling, etc.

This thoroughly excites the geek in me. I find myself fortunate to get to witness the realization of the decades-long dream of hundreds of automotive engineers worldwide. Learn more about this and many other exciting advances in automotive simulation at the upcoming Automotive Simulation World Congress, to be held in Munich on June 7 and 8.